quote:

Originally posted by CRASH_PRO:

quote:

Originally posted by Dieseljayy:

quote:

Originally posted by CRASH_PRO:

One thing I forgot to mention. I did call Sig regarding mine to increase the counter by one on people who have the issue. They told me they were aware of the problem but they have only received “one” back for this issue (must be yours). He did mention the Band-Aid solution of using a piece of Velcro (shows he read the forum since that was mentioned here).

The exciting news is he stated they are working with Badger Ordinance on creating a solution but no idea on time line. I requested to be notified if they had a solution. He wasn’t sure if it would be covered under warranty or if the price would be discounted (20% similar to the other offer going on). I also sent an email to them requesting an updated charging handle to further encourage the idea but they never replied. Personally I’m still hoping for an MPX version of the Raptor but really I would buy the first one available.

Well I posted on another site how to prevent this damage using a paperlip. Should I posted here as well?

Yes! I'm very curious to know the method used. Currently I'm doing the Velcro trick, seems to work but i also try and just lock the bolt back as much as possible.

Below is a post from another forum I wrote.

First and foremost this is not approved by Sig. Do this at your own risk. Other than that enjoy. I have over 10k rounds through my MPX and test fired over 500 with this fix. (also since I already had my barrel chopped. I don't not covered by Sig anyways. Also running a G S3G trigger without a trigger bridge so I'm already not covered by them anyways.

So currently a bunch of the people who have bought a Sig MPX know about the issue with play in the charging handle. This issue is causes by a couple of factors that went into the design of the weapon platform. They are currently working with a company to find a solution.

In the mean time anyone who wants to use their MPX might want to either never release a pulled back charging handle or cover the surface with Velcro. The issue I found with using Velcro is that the bounce can slow the entire Bolt Carrier Group (BCG) down which can cause a miss feed.

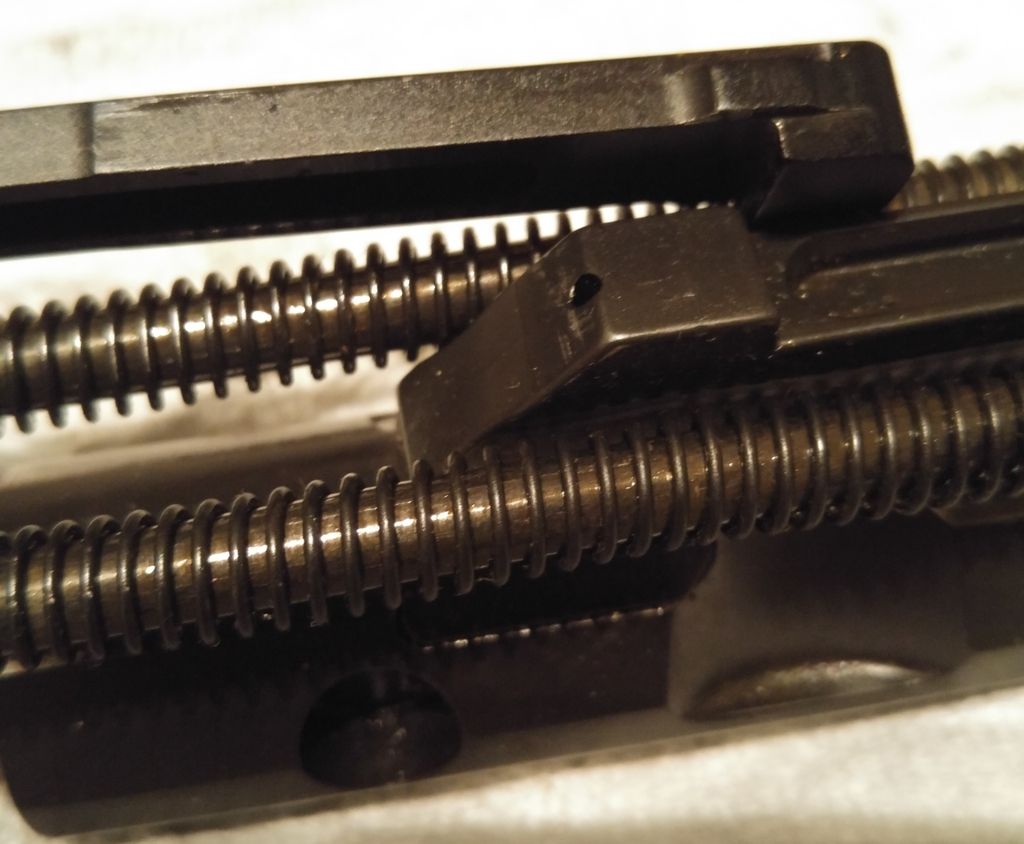

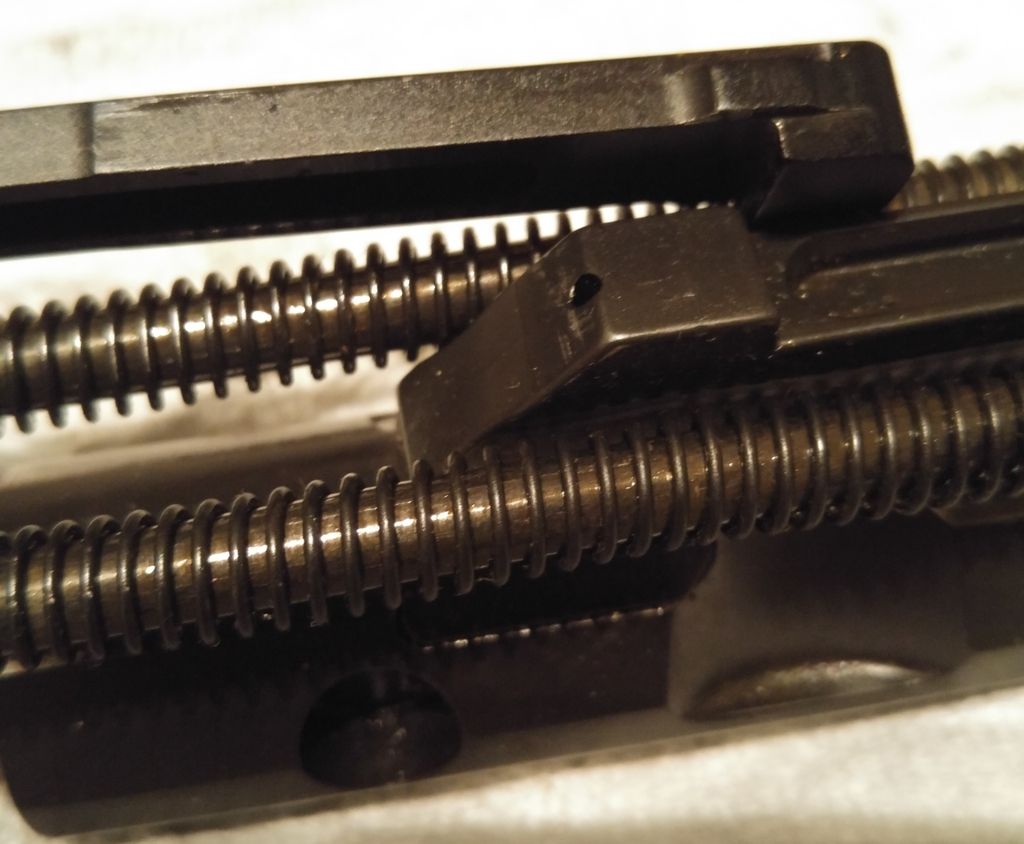

Now let's look into the source of the problem. If you have ever used/disassembled a normal AR-15 variant rifle before in your life you will notice that the charging handle has much higher ridge to it on each side. This is because the part that the charging handle pulls on to move the BCG back is the Bolt key. This is above the BCG and the recoil system of a typical AR-15. On the MPX the recoil system is above the BCG and not in-line with the BCG. I'm not going into why they did this but it makes how the charging handle interacts with the BCG different. Now instead of having a Bolt Key to pull back they are stuck with this little lip which is in line with the recoil springs. See image below:

On the MPX there is no BCKey going inside of the grove in the charging handle. This means that when the bolt cycles when the gun is fired the charging handle must now stay out of the way of that metal lip. If the charging handle had the normal height sidewalls the gun couldn't fire. The problem is since it doesn't have those high side walls it will now sag when it's pulled back causing it to bounce off the receive making marks on your receiver and the upper. See image below.

Now how do we solve this?

Well I the only thing we need to do is add something like a spring to push the charging handle up to it stays parallel to the top rail. This would prevent it from hitting the receiver when you release the charging handle. My spring of choice. A paperclip. I was trying to find a way to attach something to the piece of metal that holds the guide rods in place but since I didn't want anything that would mod the gun I used the recoil buffer to be the perfect candidate for a mounting surface.

Now all you have to do is bend a paperclip in a circle around the screw behind your buffer and tighten it down. Then bend a 45 degree angle upwards off the buffer pad. This will give the spring enough clearance that it won't hit the BCG when it cycles. Take the top part and coil it a few times so it only has a smooth surface that will be hitting the underside channel of the charging handle. Line it up so when you attach the upper it goes in front of the plate that holds the guide rods. That is all you have to do.

Now the paperclip will be applying upward force to the charging handle after it's been released preventing it from scratching up your lower receiver and your upper.

Now some to answer some concerns with this design.

1. The BCG does not impact the paperclip. It stops 3mm short of hitting my setup from the buffer.

2. I've already ran 500 round through this design and the paperclip still works like new since there is 0 stress on the paperclip.

3. The OAL of the buffer on the back of the receiver did not move closer to the BCG with the paperclip behind it when tightened down.

4. I used a thin piece of packing tap after sanding the paper clip that will be pressed by the buffer into the receiver so it doesn't scratch the receiver behind the buffer.

5. The underside of the charging handle is not scratched by the paperclip. The paperclip is to soft of a material.

6. This is my temp fix until Sig can come out with a real part. (Basically they just need to mod the part that holds the guide rod with a piece of metal pushing upward and that will fix this.) It is not complicated...

Finally legalities part 2.

Do this at your own risk. I'm not liable for anything stupid you do with your guns. If your gun is damaged by this odds are Sig will not warranty your firearm. Use common sense please. Any comments please comment below. If you need more details about the setup or more pictures please request. (as for changing out the paperclip I think it could m maybe go 3k rounds before it might let the handle drop down again.