Go  | New  | Find  | Notify  | Tools  | Reply  |  |

always with a hat or sunscreen |

Still laughing at the term "Dorito Spinner" for the rotary engine! Certifiable member of the gun toting, septuagenarian, bucket list workin', crazed retiree, bald is beautiful club! USN (RET), COTEP #192 | |||

|

Member |

Wish I could take credit for it. I remember seeing the Intel Inside style stickers reimagined to say Doritos Inside on RX cars back in the day. Hoping to avoid tool destruction when I get it mounted & go to remove the massive flywheel nut (350 ft/lb torque spec IIRC). Guy on the Locost forum, that built a 13B car, snapped a breaker bar when he tried to remove the flywheel nut. The Enemy's gate is down. | |||

|

always with a hat or sunscreen |

Some inspiration. Old '80s style Lotus shift knob   Certifiable member of the gun toting, septuagenarian, bucket list workin', crazed retiree, bald is beautiful club! USN (RET), COTEP #192 | |||

|

Member |

Thanks, I like that a lot. I know a guy that has a wood business, so may query him when I get to the point & see about a custom knob. The Enemy's gate is down. | |||

|

always with a hat or sunscreen |

Yeah the Lotus badge may not be the best choice for your "sled" build. Maybe a shift pattern engraved on mahogany like the one in my S2000 would be a better choice. Certifiable member of the gun toting, septuagenarian, bucket list workin', crazed retiree, bald is beautiful club! USN (RET), COTEP #192 | |||

|

| Member |

350 foot pounds? You’ll want one of these... Torque multiplier I use mine for my lower control arm bolts @450 foot pounds. | |||

|

Member |

Well, snapped the square bit off the swivel on my 1/2 drive breaker bar. Husky warranty put a new one in my garage, but think I'll source a 3/4 drive bar, rather than using a 1/2 to 3/4 adapter. The Enemy's gate is down. | |||

|

Member |

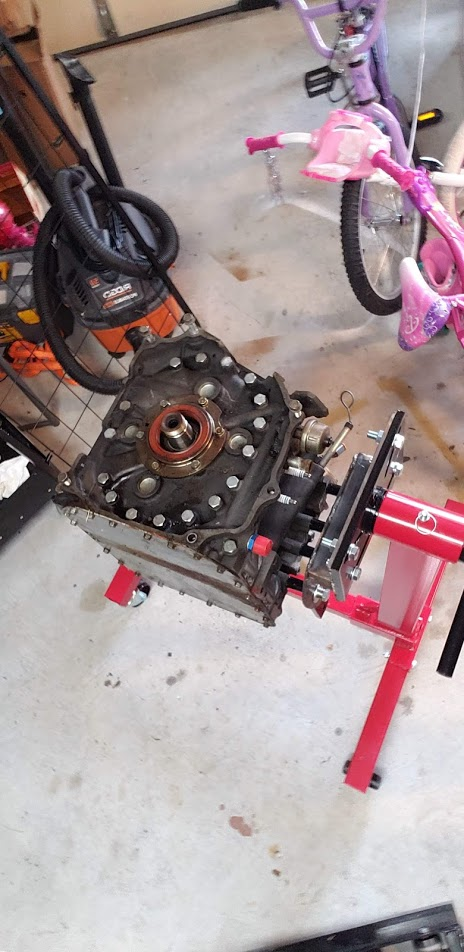

Finally some progress. After the above post, I ordered a 3/4" drive breaker bar (longer than the 1/2" that I broke, too). This also eliminated the need for the 1/2 to 3/4 drive adapter. Got a hand from my father-in-law to carry the keg outside & strapped it to the house (post between the garage doors). 3/4" breaker wit ha 3' cheater & I was suspended with both feet off the ground. A bounce or two & a loud ping, and it let loose. Bit of searching & found a handy video with the right spot to pop the flywheel with a hammer to get it loose & we're at this point.  A couple hours' work (and a decent cut in my palm where the wrench slipped while breaking loose the tension bolts) later & she's an exploded Dorito spinner. Cursory first look, nothing looks awful inside. Need to get it all cleaned up & do some more thorough examination. The rotors are a bit sludgy, to the point that the apex seals didn't fall out when removing them from the housing. Fingers crossed that she's rebuildable without needing to replace much, other than seals/springs. Pretty amazing that an entire short block is only about 20 major components. Need to get some good degreaser & a suitable parts washer container & start cleaning things up. Hence my other thread looking for some good products.  The Enemy's gate is down. | |||

|

Member |

Got out to the garage a bit over the weekend & got the front rotor torn down. All seals & springs removed. All of the apex seals were cracked in half, laterally. All of the seals took some work to remove, and they're supposed to be free-moving in their slots. Broke a couple of the side seals as well trying to pry them out. Cleaned up the rotor a fair bit & need to get to the rear rotor. Then it'll be the housings & making the call on whether it's salvageable or if buying a used/running engine is more worthwhile. The Enemy's gate is down. | |||

|

always with a hat or sunscreen |

So what's the word? Salvageable Dorito spinner or a need for a good shape used twirler? I can't wait until you put that custom wood shift knob on your Super 7 Rotary sled! This has got to go! LoL   Certifiable member of the gun toting, septuagenarian, bucket list workin', crazed retiree, bald is beautiful club! USN (RET), COTEP #192 | |||

|

Member |

Unknown yet, only got 1 rotor torn down. Still need to do the other & clean up the housings [block] and see how it all looks. The Enemy's gate is down. | |||

|

always with a hat or sunscreen |

Gotcha. Take care and keep us posted. Certifiable member of the gun toting, septuagenarian, bucket list workin', crazed retiree, bald is beautiful club! USN (RET), COTEP #192 | |||

|

Member |

In a stroke of luck, another user on the Locost forum says he may have a spare [full] set of apex seals/springs, if he can find them he'd mail them my way. That'll save $4-500 off the build. The Enemy's gate is down. | |||

|

| Member |

Damn, I used to love to work on projects, mainly my Prelude. I'm getting to old anymore! A days work as a plumber kicks my ass. Hopefully get back into my Prelude shortly!! _________________________________________________ "Once abolish the God, and the Government becomes the God." --- G.K. Chesterton | |||

|

Member |

Which Prelude do you have? When I worked at a Honda dealer in college, we had 2 guys with 5th gens 1 was a base 5mt, that was immaculate & rarely saw vtec, the other was a SH that was a bit rough. Another guy I knew had a RHD JDM import, can't remember the model, might've been a Type S. Fun cars, got a couple drives at low speed in a RWS 3rd gen. Turned like on rails. The Enemy's gate is down. | |||

|

| Member |

I agree on removing the Ospho, it can cause problems. I have mostly used a hand wire brush to remove the excess Ospho. If it was my project, I would have the frame sandblasted. For paint mostly I would use two part epoxy sprayed on, then LPU on top. To spray epoxy, the best low cost method is to heat up about half a quart of mixed epoxy in a microwave oven. Only go about 7 seconds in the microwave, so the pot life will be 3-5 minutes. Two part epoxy is SUPER strong, and the LPU on top looks great. However there is a process where the entire frame can be dipped, and this might be better, but I know little about that system. -c1steve | |||

|

Member |

Learned something new today. Apparently, Mazda has bounced back & forth between 2 & 3 piece apex seals. I have only ever seen the 2-piece & as such, thought mine were all broken length-wise. Supposedly, the 3-piece, in N/A engines, seals better than the 2-piece seals. 2-piece is/was the only OE spec for boosted engines, I believe. Just need to get the other rotor torn down & inspect all the seals, and I may be in good shape The Enemy's gate is down. | |||

|

| Yew got a spider on yo head  |

That's cool! Is it ported? Is there a plan to? | |||

|

Member |

Stock porting for now. Undecided if I want to street port it. Found out this week that the 9k rpm Renesis is compatible with the rest of the drivetrain, so sourcing one of those as a down the road upgrade may be a plan. The Enemy's gate is down. | |||

|

Member |

No updates, haven't touched it in a couple months. Still need to pick up some steel & finish the chassis. Latest conundrum: Refurb the engine I have, or 'upgrade' The engine I have is a 13B-S4 from an early first-gen RX-7 At minimum, it needs: Side seals & springs, apex seal springs, corner seals & springs (maybe not all 12), intake manifold & throttle body. And that's if the apex seals are all in good enough shape to re-use. 'Upgrade' option would be a 13B from an RX-8 (13B-MSP), of which there are 2 flavors, 4 port & 6 port. The 4 port is the cheaper & simpler option to go with & makes about 60hp more than the S4 I have. The 6 port is more of a challenge, but makes another 40hp over the 4 port MSP, and gets a 9k RPM redline Locally, both are available for about $1k & $1,600 respectively, and everything I've read says all 13B engines are compatible with any 13B drivetrain, so I should be able to use the 5 speed & LSD I have & not have to worry about having another driveshaft made. The 4 port is an auto & would need a clutch/flywheel, and both would likely not be compatible with my fairly old Haltech E6k ECU. If I jump on an MSP, I suppose I could attempt to sell the S4 & recoup some of my costs, or keep it & finish rebuilding it & street port it into a 'down the road' upgrade. The Enemy's gate is down. | |||

|

| Powered by Social Strata | Page 1 2 3 4 5 6 7 8 9 |

| Please Wait. Your request is being processed... |

|

© SIGforum 2025