SIGforum.com  Main Page

Main Page  SIG Pistols

SIG Pistols  A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)

A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)

Main Page

Main Page  SIG Pistols

SIG Pistols  A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)

A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)Go  | New  | Find  | Notify  | Tools  | Reply  |  |

Member |

I've never used wolff recoil springs, but I know Bruce Gray developed his "fat guide rod" for use with aftermarket recoil springs. Wolff springs are single wire and could get hung up in the slides recoil rod hole. I think there used to be a picture a stuck recoil spring on Gray Guns website. The fat guide rod would be cheap insurance if your running aftermarket recoil springs. | |||

|

| Go ahead punk, make my day |

I've seen a pinned breechblock SIG lose the inner pin and the MX guide I have seen says 5K to ensure it is pinned in place properly to reduce movement that may translate greater stress to the frame. | |||

|

| Member |

Glad you got your hands on the real P228 springs I am finding out some weird stuff lately about several other recoil springs. when comparing the new white spring to the factory original spring in my 1990s vintage P229 in 357sig, they look way different. obviously part of the reason is due to the caliber difference, but the factory 357 spring is much longer with noticeably more spacing between the coils. they technically shouldn't be that different. I am now interested to buy a new 40/357 spring (blue paint), to see how they compare. | |||

|

| Ignored facts still exist |

I like the idea of Wolff as an alternative, but the questions then becomes, which Wolff, since they have several of different strengths. . | |||

|

| Member |

Also, I believe I have all but confirmed that the P226 9mm orange paint recoil spring and the factory spring in the stamped slide German and West German P226 models is one and the same spring. I'm not sure if I originally posted that on this thread. But anyway, they look identical, save for the paint (i.e. spacing between coils, overall length, number of coils is the same). I can also say that they seem to "feel" the same when racking a slide, but obviously couldn't tell for sure if they were identical in that respect. Hopefully the strength/weight is the same between the two | |||

|

| Ignored facts still exist |

regarding the cracked frame from page 6.... Would a steel frame be more rugged in this regard, or would steel have suffered the same fate just as easily as the standard P228 alloy frame? . | |||

|

| Member |

A steel frame would have likely been more rugged as you say, but certainly not indestructible by any means. When the recoil spring stops doing its job, the locking insert and takedown lever (which act as though they were one single piece, during normal function) are taking a lot of force, and in turn, they are impacting the frame. This is steel exerting a large force on aluminum, not good. By that logic, a steel locking insert and steel takedown lever exerting a large force on a steel frame,-->better, but still not good. This same analogy could be drawn for Glocks, to be taken as the worst of the three, since they have steel locking inserts in polymer frames (though the construction is a bit too different to make it a direct analogy) bottom line, a steel frame would have been more durable, since everything would be steel on steel contact | |||

|

| Member |

Quite impressive Q! Thanks for sharing that. Great stuff man. | |||

|

Oriental Redneck |

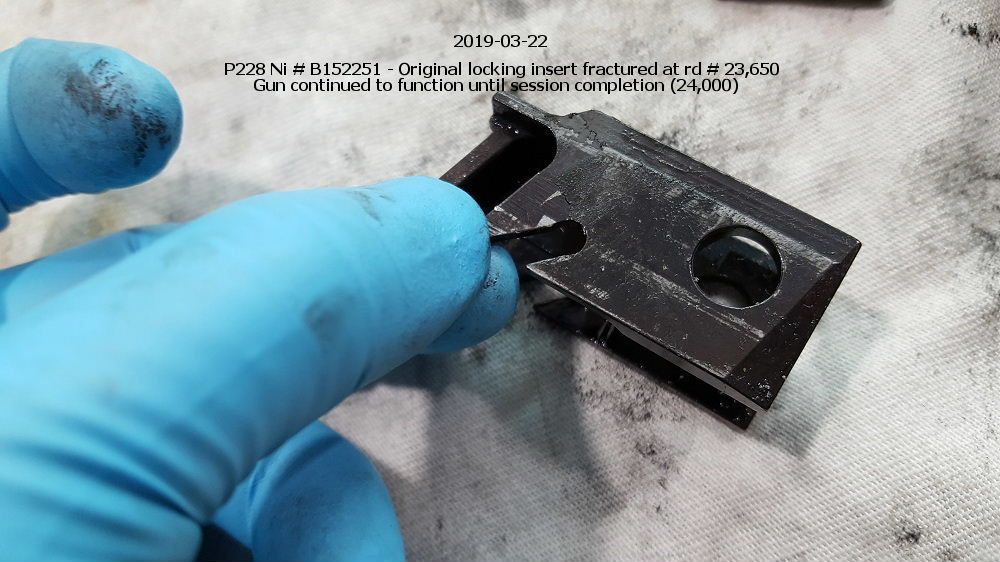

Yes, there is. I went back and reviewed all the pics that I took, and the chipping away of the metal has been there much earlier, but was less pronounced.         And, I've been racking my brain trying to figure out what could have done that. When I pieced things together and tried to see, there is nothing that comes into contact with that part. At least, nothing when the gun is static. But, clearly, during firing, something has been chipping away at that area, as evidenced by the pics. And, eventually, the stress led to the >fracture of the the locking insert's tooth<?   Q | |||

|

| Member |

Very interesting. Anyone else have a high round count Sig to see it wear in that area is common? Q, what does the bore look like after all those rounds? When buying used some people like to have a pic of the rifling. Perhaps a few good pics of the locking part of the barrel would tell a better story. | |||

|

Oriental Redneck |

I'll post pics of the 25k bore, next to a brand new P228 barrel, when I get a chance. Of all the tons of pics I took, I didn't take any of the bore at intervals. Now, onto another subject that I've been wondering about, for those that shoot a lot and a lot. Looking at my schedule of shooting and the amount shot during this time, do you think that was excessive? Just a couple of examples, 4000 rds in 4 straight days (2/19 - 2/22), 5000 rds in 5 straight days (3/19 - 3/23). And, a thousand rds typically lasted about 40 minutes of continuous shooting. Could this also have contributed to weakening of the frame? I've never shot like this before, so I don't know. Q | |||

|

| Bookers Bourbon and a good cigar  |

Possibly heat induced failure. If you're goin' through hell, keep on going. Don't slow down. If you're scared don't show it. You might get out before the devil even knows you're there. NRA ENDOWMENT LIFE MEMBER | |||

|

| Member |

If I were a bet on what caused the rail failure it would be not replacing the breech block roll pins. I had a German 226 rail crack at around 9,200 rounds on the same set of roll pins. The recoil spring was changed every 3,000-4,000 rounds. This is a well known issue. There are a lot of quality threads at pistol forum regarding Sig durability, slide velocity, small parts quality, maintenance and more. The late Todd Green contributed so much valuable information from his time at Sig and his experience with Sig pistols. I will dig up the links and send you an email. Todd also stressed that the roll pins needed to be replaced at every 5k or you will see the breech block and/or rails break. | |||

|

Oriental Redneck |

Thanks for this. While I don't doubt his expertise about the factors contributing to failure, my suspicion is that the extreme shooting might also have been a factor. Do you know of anyone who has shot similarly, and what was the outcome? I seriously am curious. I have no intention of ever shooting like this again. It was a very fun experience, but quite exhausting at the same time. Q | |||

|

| Ignored facts still exist |

Speaking of the Breech Block Roll Pins, are these still made, and if you were to buy some today, does anyone have a part # and supplier? Turns out, I never replaced mine . | |||

|

| Member |

Todd averaged 350-550 rounds per hour through his P30 test gun before it broke at over 90,000 rounds. HK concluded it was heat that caused the frame damage. Does this apply to an aluminum framed Sig? I have no idea. https://pistol-training.com/archives/2668 | |||

|

| 7.62mm Crusader |

Did you ever see the Remington Arms ads for their Nylon 66 semi auto .22 rifle ? I'll bet you did as a kid Q. He shot over 100,000 wood blocks thrown up in the air. That lil .22 still shoots today. Tom Frye was his name. | |||

|

| 7.62mm Crusader |

I remember one competition shooter fireing 500,000 rounds of .38 Special through a custom S&W revolver in preperation for the Bianchi Cup. His practice paid off as he won. | |||

|

| Freethinker |

A post of possible interest to those desiring to keep their SIG pistols going as long as possible: https://sigforum.com/eve/forums...0601935/m/6801056451 ► 6.0/94.0 To operate serious weapons in a serious manner. | |||

|

Oriental Redneck |

Q | |||

|

| Powered by Social Strata | Page 1 2 3 4 5 6 7 8 9 |

| Please Wait. Your request is being processed... |

|

SIGforum.com  Main Page

Main Page  SIG Pistols

SIG Pistols  A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)

A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)

Main Page

Main Page  SIG Pistols

SIG Pistols  A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)

A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)© SIGforum 2025