SIGforum.com  Main Page

Main Page  SIG Pistols

SIG Pistols  A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)

A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)

Main Page

Main Page  SIG Pistols

SIG Pistols  A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)

A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)Go  | New  | Find  | Notify  | Tools  | Reply  |  |

Member |

Thanks for reporting phase 2, Q. Ni finish held up admirably. That P228 is getting a well deserved “spa” day at SIG. I do not believe I could do four one thousand round days in a row. Happy to hear you held up well also! “There is love in me the likes of which you’ve never seen. There is rage in me the likes of which should never escape." —Mary Shelley, Frankenstein | |||

|

| Member |

Shucks! I was hoping to see how many rounds it would take before small parts/springs started to break. Thanks for doing this! | |||

|

| Member |

When you send a stamped slide gun in for the full service package, do they mess with the anything about the breech block (like replace the roll pins or something), or do they just leave it alone? | |||

|

Oriental Redneck |

It is complete tear down and cleaning. The roll pins, among other things, are replaced. Q | |||

|

| Member |

Q, Where did you find those grips? | |||

|

| Freethinker |

Great report. Thanks! ► 6.0/94.0 To operate serious weapons in a serious manner. | |||

|

| Member |

Q, Any perceptible change in the trigger weight and feel over the 20k rounds? | |||

|

| 7.62mm Crusader |

Something that keeps coming back to me concerning the nickle finish. While many have said the frame gets stripped of its original anodized finish, something I wonder about. Q, I've done some chem dipping in a factory many years ago. It was to remove any film and preservative on sheet metal parts prior to plating. And yes, some form of nickle was used, not by me. What are the odds Sig may have sent bare frames and slides for plating and no stripping was ever done? It just doesn't make a lot of since to plate, strip and replate. Most companies would not do this. | |||

|

| Member |

If I could give my $0.02 before Q answers your question. The full-nickel guns are rare, but I do not think they were rare enough that all of them were made to order. Nor do I think they were common enough to be considered as standard production as the non-nickel guns. I could be wrong about that, but if I am right, then it would seem to me that the only way that sig would have sent bare frames, is if they "knew/planned in advance" exactly how many guns would become nickel ones. They could send bare frames if the guns were made to order, because they easily just take a few off the rack before they would go and get anodized, and send them out bare, since it is just a small made to order number easy to keep track of on an erratic basis. Also if they were very very common, then they could just have separate large batches of frames that are destined to not be anodized. Somewhere between those two lies a middle ground, and while it is possible that sig had very small batches of frames destined to not be anodized, it seems to me that they could more easily manage inventory by just having all of them anodized and then have the ones meant to be nickel stripped afterwards, especially seeing as how that was an operation happening not only outside of Sig Sauer's manufacturing facility in Germany, but all the way over here in the States | |||

|

| 7.62mm Crusader |

Thank you. I dont know about batch size or made to order but it did just come to me the West German and German guns were not completed here in the US so they definately would have started out as black guns. Good enough. Now the later nickle models like the bar stock slide guns may have been made in batches to be anodized silver and nickle slides. | |||

|

| Member |

true enough for sure about the American-made guns. as for the older German guns, one idea would be to dimensionally compare a factory nickel gun in all-original condition, to a black gun that has been refinished, only once from new, in nickel. still though, I think dimensional differences between the two would be within manufacturing tolerances. I don't believe that stripping the anodizing honestly takes off the drastic amount of metal that people think. but, grain of salt | |||

|

Oriental Redneck |

I bought them a while ago, here and there, when they were still plenty.

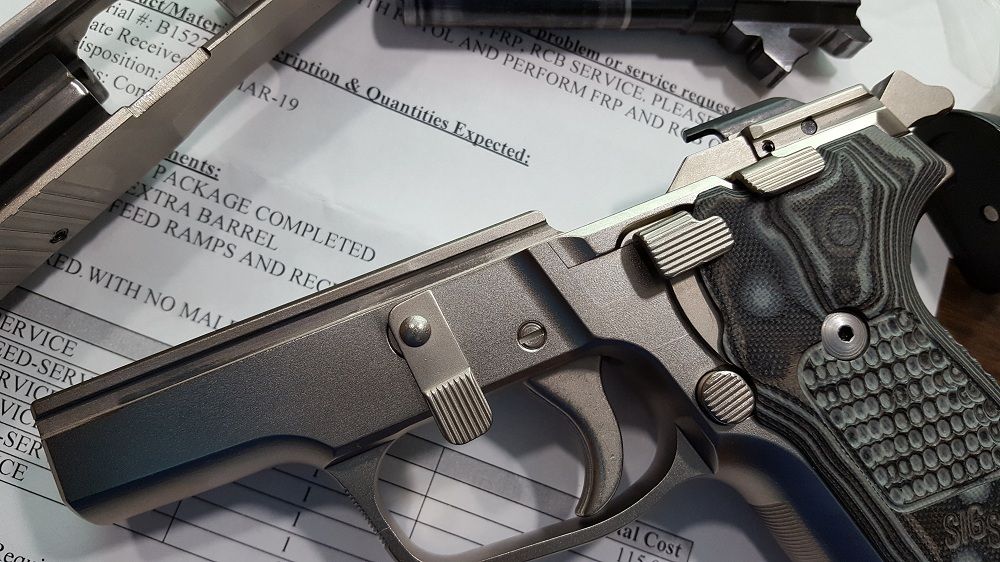

The trigger was very good in the first place. But now, it is even better. Smoother and a touch lighter in DA. The SA really shines, I'd say about 4 lbs and so crisp (at almost the level of a Robert Burke's work).

David, this has been discussed previously in this thread, Klein Electroless Nickel (EN). Here is a direct quote by Joe Dudenhoeffer, the current President/owner of Klein, who started at Klein years ago as an employee doing the plating works.

Q | |||

|

| Member |

Great test and professional quality report. Very interesting to see how the gun holds up. It seems the German made P228 is a remarkable artifact, it has so many good qualities in a single package. | |||

|

Oriental Redneck |

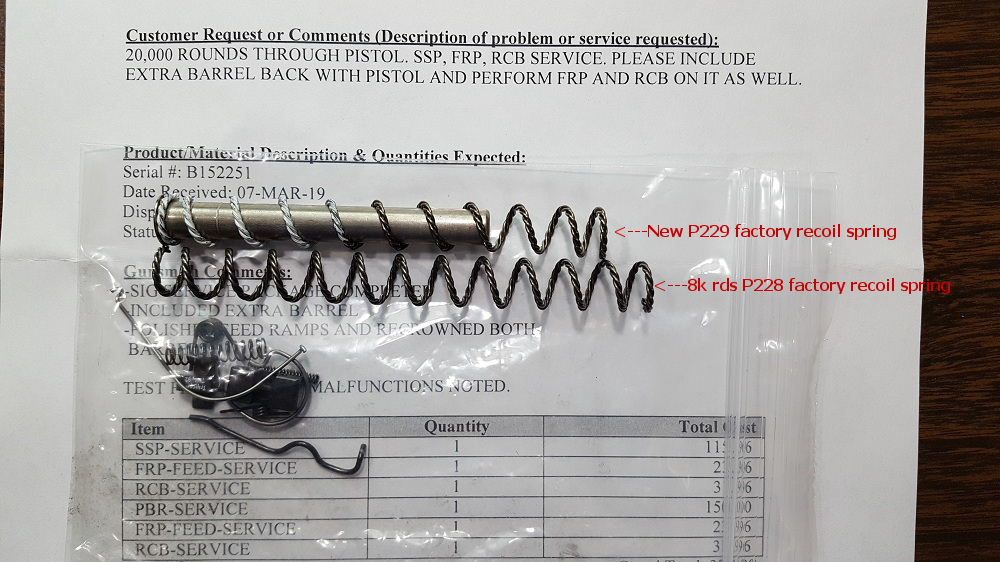

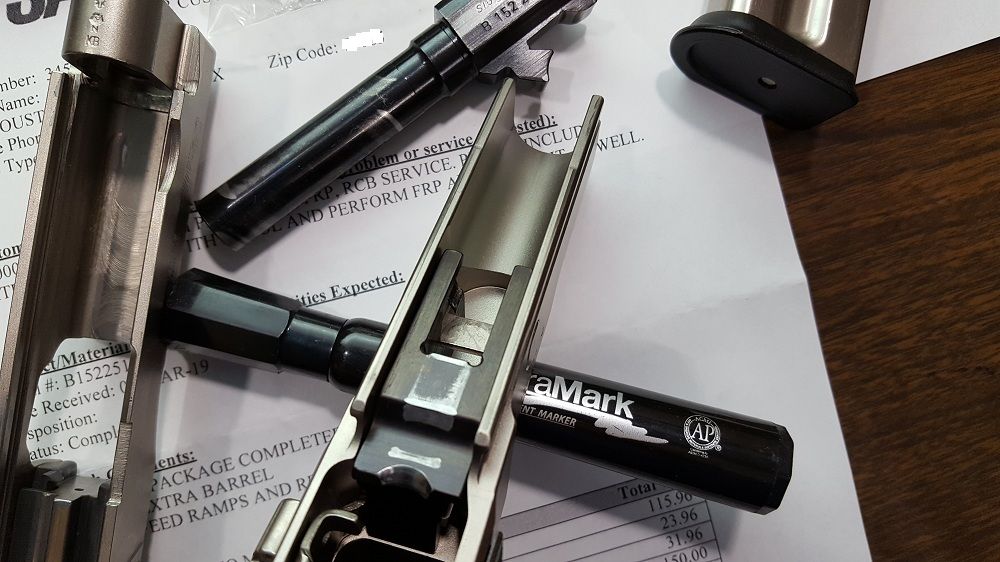

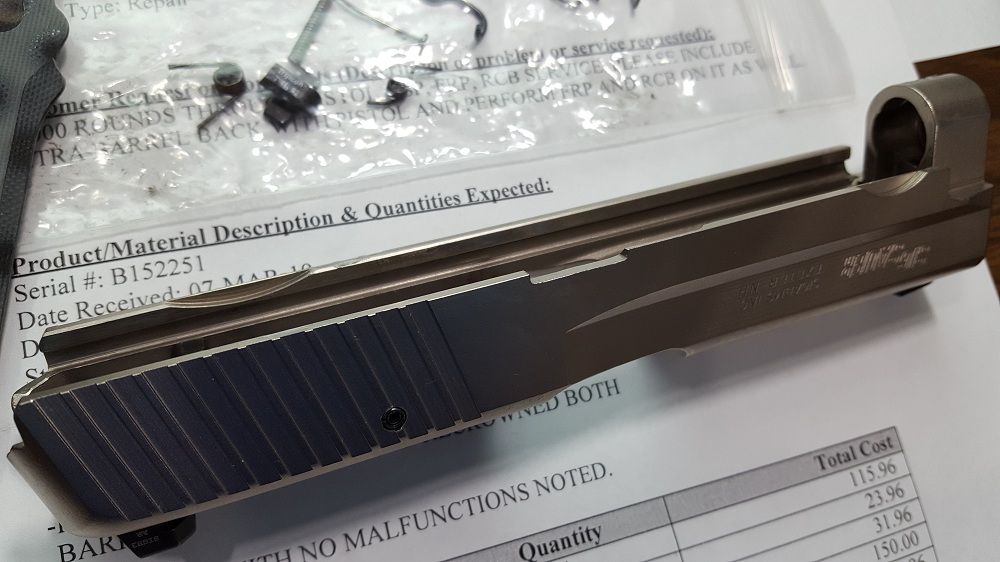

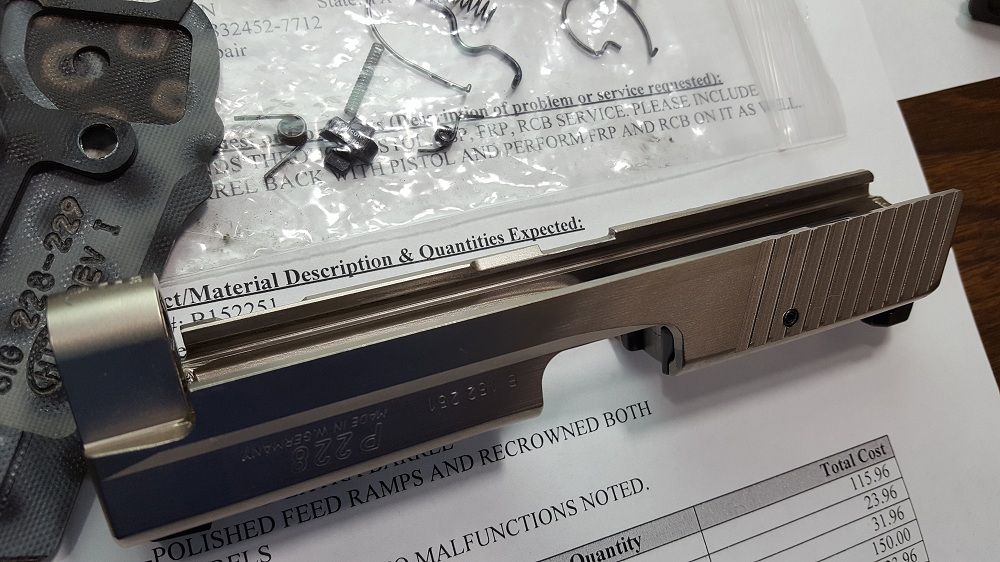

*** This will be the final report on this little guy. *** Gun came back from SIG on 3/18 after SSP. Almost as good as new. As noted in another thread, the new white P229 recoil spring is shorter and weaker than the original P228 spring.  Also, a couple of things that really annoyed me about the factory service that has never happened before with all my other SIGs sent in. 1- The roll pins were not replaced. 2- The gun was nearly bone dry devoid of lubrication, except for the hammer/sear area. I knew this was a sloppy job by some of their workers. So, I emailed the new CSR that started working with me on this gun and asked if SIG had changed lubing and roll pins replacement protocols. I got a reply 5 days later that I knew was total BS, instead of an admission of the screw-up and an apology.

Really man? Even your company website says, under the SSP, "Reassembly and lubrication to factory specifications". Factory specs doesn't mean only the hammer/sear area gets greased. Man, I hate it when the so-called experts try to pull one over you. I know, lubing the gun is easy, I'll do it myself. But, this is about carelessness in servicing your gun and then tried to BS you.

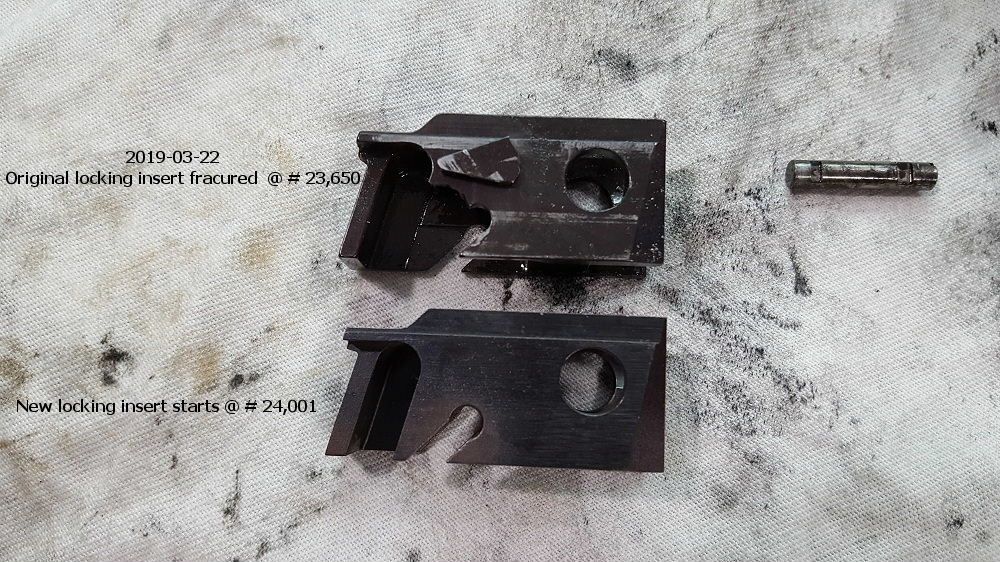

I told him to just send me the roll pins, and I can do it myself. But, it's really meaningless, now (see cracked frame at 25K, last 6 pics at bottom of this post).          Onto the next phase of testing. I was planning on another 10k before month's end. But, sadly, it only got to the halfway mark, then everything fell apart. Ammo: Magtech 115 FMJ (4000 rds) and Magtech 124 FMJ (1000 rds) Range days: #1- 3/19: 1000 rds #2- 3/20: 1000 rds #3- 3/21: 1000 rds #4- 3/22: 1000 rds #5- 3/23: 1000 rds On the 4th day, at round # 3650 (total # 23650), the trigger was stuck and failed to reset. I thought it was due to so much crud inside. I jiggled it a little and it reset. Then, I looked down on the platform, there was this little piece just laying there. Had no idea what it was. I took off the slide and did some inspection. Nothing out of the ordinary jumped out. So, I put the piece away to study it at home, put the slide back and continued shooting until ammo ran out (#24,000). There was no further malfunctions. But, I think this proved to be a fatal mistake I made for the gun. When something fell out of your gun, you don't continue shooting. When I got home and took everything out, there it was, the locking insert was fractured. Of all the things that can break, the locking insert is the last thing I expected to go first. Luckily, I have 2 spare locking inserts. So, I put the new one in, and the gun was ready for more action. The 5th day went uneventfully.       Today, 3/25, was cleaning gun day getting ready for the next session. But, sadly, there will be no more range days for it. RIP.       Looking back, what could have done differently that could have averted this catastrophic failure? Suggestions?This message has been edited. Last edited by: 12131, Q | |||

|

| Member |

Damn I hate to see that happen Q! I was hoping for at least 50K before anything and hopefully even more. I have no helpful thoughts, sorry. | |||

|

| 7.62mm Crusader |

I dont know the mechanics of the locking insert but this makes me look strongly at that main spring. Some type of battering of the upper. That is sad to see. Visible is the smearing of metal along the rear bottom of the frame rail. Almost like upward pressure as the slide recoiled. | |||

|

| Member |

Q, I am pretty sure you did everything almost perfectly. there are only two things I can think of that might have made the gun last longer: One, you should have changed the original recoil spring earlier in the round count (while I do not think that was a catastrophic mistake as it is often made out to be, leaving it in for that long definitely contributed to some extra wear and tear). And two, I wouldn't have let that P229 white paint spring anywhere near the gun (had I known). you didn't know first hand, and I wouldn't have noticed it either. hindsight is 20/20. I don't see any other reason that the locking block could have failed, but you never know. everything else you did was great. in fact, I was very impressed by how well the gun was lubed. the outside of the barrel showed nowhere near the amount of wear I thought it would after that many rounds. | |||

|

| Member |

it's gotta be the spring. if you look at fixed barrel guns that have delayed blowback, you will notice one thing in common between them, they have rubber recoil buffer pads to keep the frame from taking too much force. On a sig, as well as any other browning-action gun, the recoil spring serves that exact purpose, in addition to putting the slide back in the forward position. | |||

|

Security Sage |

The 8k spring should already be compressed more than a brand new 228 one. Throw in an incorrect spring that could be up to an inch too short, and that’s sure to contribute to a crack in the frame. Sad to see. RB Cancer fighter (Non-Hodgkins Lymphoma) since 2009, now fighting Diffuse Large B-Cell Lymphoma. | |||

|

Oriental Redneck |

Yeah, the 12k original P228 spring was a mistake. The 8k next P228 spring was the second mistake. Although the naked eye could not see the likely micro damage that was already happening, the 3rd mistake of trusting the white P229 spring was the final nail in the coffin. Lesson learned: Springs are cheap. Guns are expensive. Q | |||

|

| Powered by Social Strata | Page 1 2 3 4 5 6 7 8 9 |

| Please Wait. Your request is being processed... |

|

SIGforum.com  Main Page

Main Page  SIG Pistols

SIG Pistols  A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)

A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)

Main Page

Main Page  SIG Pistols

SIG Pistols  A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)

A 5 weeks 10,000 rounds report on a Klein Ni P228 - Lots and lots of pics. /// ** 20k ** (p.4) /// *** RIP @ 25k *** (p.6)© SIGforum 2025