SIGforum.com  Main Page

Main Page  The Lounge

The Lounge  Any other benefits aside from longevity with Platinum and Iridium Spark plugs over copper?

Any other benefits aside from longevity with Platinum and Iridium Spark plugs over copper?

Main Page

Main Page  The Lounge

The Lounge  Any other benefits aside from longevity with Platinum and Iridium Spark plugs over copper?

Any other benefits aside from longevity with Platinum and Iridium Spark plugs over copper?Page 1 2

Go  | New  | Find  | Notify  | Tools  | Reply  |  |

Only the strong survive |

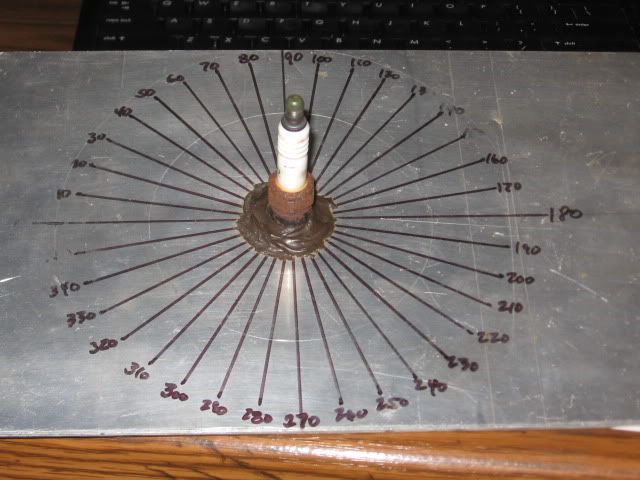

When we raced stock cars back in the 60's, we used washers under the plugs which was a lot of trouble. My way can be used on any engine. What you are trying to do is determine where the thread starts on the spark plug hole. You will need an aluminum plate about 10 inches square with a hole drilled in the center and a plug insert epoxied in the hole. The plate should be marked off in a 360 degree radius with 10 degree radi as shown in the picture.  What you are trying to do is find a reference point and in my case, I used the 12 o'clock position of the spark plug hole. So you take an old plug with masking tape wrapped around the spark plug top and screw it in #1 cylinder tight. Take a felt pen and mark the 12 o'clock position on the top edge of the plug. You may want to check a second time and use new masking tape each time to mark as accurate as possible. Take the plug out and screw it into your reference plate. Now see where the mark lines up on the plate. Lets say it is at 170 degrees. Now that tells you that the #1 cylinder at 12 o'clock position is 170 degrees. On a Chevy small block, the exhaust valve is at 10 o'clock and the intake is at 2 o'clock approximately. So now you want the plug to face the intake valve which has a good view of the plug from 12 to 3 o'clock or 0 to 90 degrees. So now you can calculate that you want a plug that the open electrode faces in the range of 170 to (170 + 90) 260 degrees. So on #2 cylinder, you measure the 12 o'clock position and it turns out to be 240 degrees. Since the intake valve is on the left, you subtract 90 degrees from the 240 degrees and get a range of 150 to 240 degrees for #2 cylinder. Measure all the cylinders with the reference plug and note the 12 o'clock position for all the cylinders. Calculate from the reference 12 o'clock position, the range of view to the intake valve or injector location. This is so easy, SigMoney could do it. You can check your work when using the spark plug you have selected for a particular cylinder. Place the spark plug on the socket and use a piece of tape on the extension and mark which way the spark plug gap is facing. Then as you screw the new plug in, you can see whether the orientation is correct. The Chevy small block uses a 14 MM insert.This message has been edited. Last edited by: 41, 41 | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

SIGforum.com  Main Page

Main Page  The Lounge

The Lounge  Any other benefits aside from longevity with Platinum and Iridium Spark plugs over copper?

Any other benefits aside from longevity with Platinum and Iridium Spark plugs over copper?

Main Page

Main Page  The Lounge

The Lounge  Any other benefits aside from longevity with Platinum and Iridium Spark plugs over copper?

Any other benefits aside from longevity with Platinum and Iridium Spark plugs over copper?© SIGforum 2025