Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| Peace through superior firepower |

I pulled one of my old Minis out of storage to wipe it down. I put it away almost 8 years ago and haven't touched it since. I discovered that I had it stored all this time with the hammer cocked and if you're wondering if the hammer spring on one of these Rugers will take a set if left cocked for so long, it does. I have other Minis to compare it to and it's apparent the hammer spring has lost some strength. I ordered a replacement from Wolff- a standard power spring. I know how to get the spring and strut assemby out. It's the getting the old spring off the hammer strut and the new spring on the strut that might be a problem. One guy on youtube recommends using a drill press. You can see his method here. I don't have a drill press. I do have a vice, but it's not mounted at this time. Any suggestions? As you can see, Ruger uses a capture pin for replacing the hammer spring. I just need to be able to compress the spring enough on the strut to get the capture pin in place, and then it's a piece of cake getting the assembly back in the trigger housing. | ||

|

"Member" |

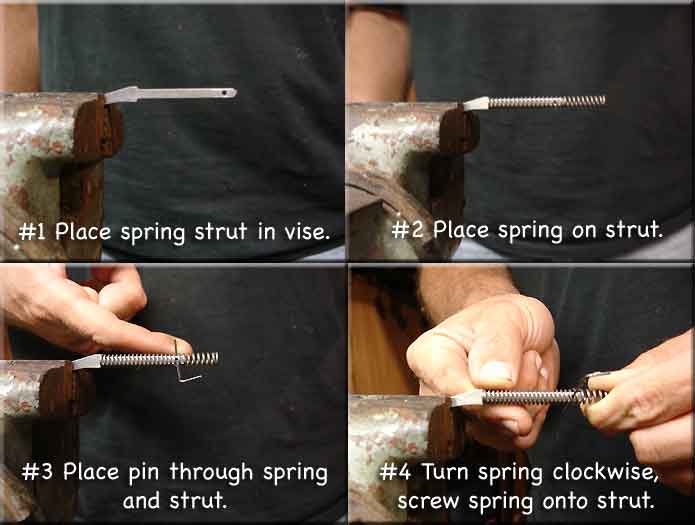

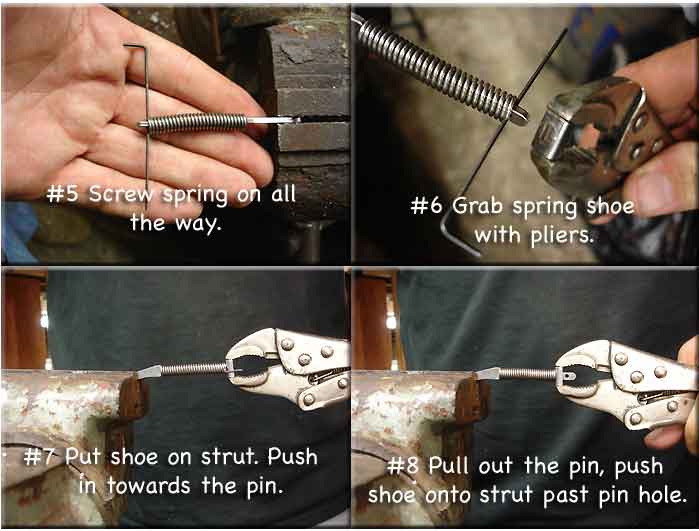

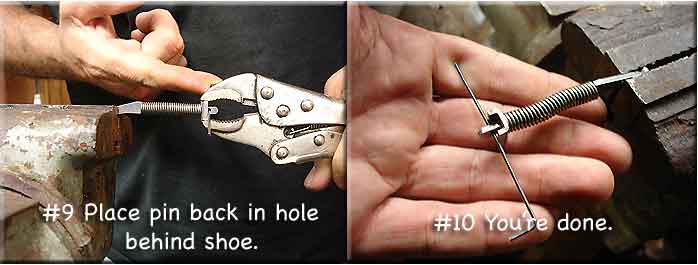

I changed one decades ago, but honestly I have no recollection of it. It would appear similar to the Ruger pistol struts. Depending on the "tightness" on the coils, and the ends, you can use this method. Though after doing many of them, I no longer bothered screwing them on all the way, didn't need to. Use a very thin allen wrench as a your temporary pin. Since there's no shoe, it won't be the same, but the idea is similar.    Since there's no "shoe" at the end of the spring, once you have the temporary pin in, you use some other object with a gap in to compress the spring. Like this, just without the shoe. "fork method"  How well this will work obviously depends, I assume without the vise bolted down it would be fussy, but you may still be able to do it. Funny how old / poor those pictures are. I don't even think they were digital pictures, but video captures. I made that a LONG time ago now. | |||

|

| SIGforum's Indian Off the Reservation  |

I don't have a Mini 14, but have to say, cas, that is some excellent thinking outside the box! Good luck boss. Mike You can run, but you cannot hide. If you won't stand behind our troops, feel free to stand in front of them. | |||

|

| Peace through superior firepower |

Thanks. I've changed out mainsprings of the Ruger GP100, SP101 and the Six series just by hand. The shoe makes it easy. The Mini-14 hammer spring, on the the hand, has no shoe and is substantially larger and stronger. I don't think the fork method will work. The Vise-grip/vise method might work, if the Vise-grips are adjusted very carefully. I'm concerned about bending the strut or marring the end of the strut in vise jaws. Thankfully, this is not a top priority to get it changed out. Obviously, this rifle is not being used actively. | |||

|

| Member |

I tried to do one on mine years ago but couldn't do it without a press,like in the video. Eventually, I wound up buying an assembly for mine from Numrich-Product #: 1528270A and is around $8.00 plus shipping, as it has the spring already pinned on the strut. There are a few other places like Midway and such that sells the whole assembly. For me it was much easier as that spring strength is something not of this world. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

© SIGforum 2025