Go  | New  | Find  | Notify  | Tools  | Reply  |  |

Member |

Received mine today as well, though I have to say I am not 100% pleased with it, and here is why: >Installation experience was same as Ted: very snug fit, spring clicked right into the retention slot, no problem. > The base plate is wider than the factory plat, so much so the rear of the plate produces a very noticeable protrusion when I grip the pistol with my right hand, so much so I can feel it digging into my pawn. > The material almost appears to be 3D printed. Not that there is anything wrong with it, just hope that it ain't gonna cause the magazine to do a spontaneous disassembly at the range. I'm going to see if there is a way to smooth out the corners of the base plate. Pictures:       | |||

|

| Banned |

I noticed a little bit of that on my palm in right hand but was not really bothered by it. Maybe just my old sailor calloused hand. LOL I think a really fine jewelers file can easily fix that if it's a real bother | |||

|

| Member |

Thank you everyone, I just got back and mine were very easy to put on and fit me great. That seller on e-bay is the same one I used. | |||

|

Member |

Yeah I think I will take a file/sander (if it's really needed) to it and see if I can smooth it out a bit. My hands aren't exactly...big, so any protrusion can be easily felt :P But glad to hear the protrusion isn't just "unique" to my baseplate! | |||

|

| Banned |

As I expected a few strokes of a very fine jewelers file easily solved the slightly wider base rough edges. Did both sides of all three of my mags and now not even a hint of a palm "bite" with either hand. | |||

|

| Banned |

Well Mech your concern about disassembly may be a problem. One of mine has cracked at the base along the grove holding it to the mag and come off. I had yet to use it for firing. Separation was just from fully loaded mag pressure since installation. I'm now very sceptical these will hold up at all. | |||

|

| Member |

I used a Pearce PG-XD grip extension and a P229 baseplate and made my own...had to do a little Dremel work and utility knife shaving but it is rock solid and has worked well for over a year.  IMG_7949 (800x600) IMG_7949 (800x600)  IMG_7951 (800x600) IMG_7951 (800x600)  IMG_7952 (800x600) IMG_7952 (800x600)  IMG_7955 (800x600) IMG_7955 (800x600) | |||

|

| Banned |

I've gone back to OEM and think I will go that way as I have plenty of P229 mags to cannibalize. While the OEMs are no thicker in the area that cracked, it appears the OEMs are molded instead of cut/machined. Thus maybe the eBay plates wind up weaker or easily flawed in the crack area. BTW did you bend the P224 springs as shown in the link here showing how to do the PG mod? | |||

|

| Member |

If I remember correctly if the P229 baseplate is used then I didn't need to bend the spring but if you just swap out with the PG then the spring needs to be bent...tried that first and the spring hung up a bit and didn't like that | |||

|

| Banned |

| |||

|

| Member |

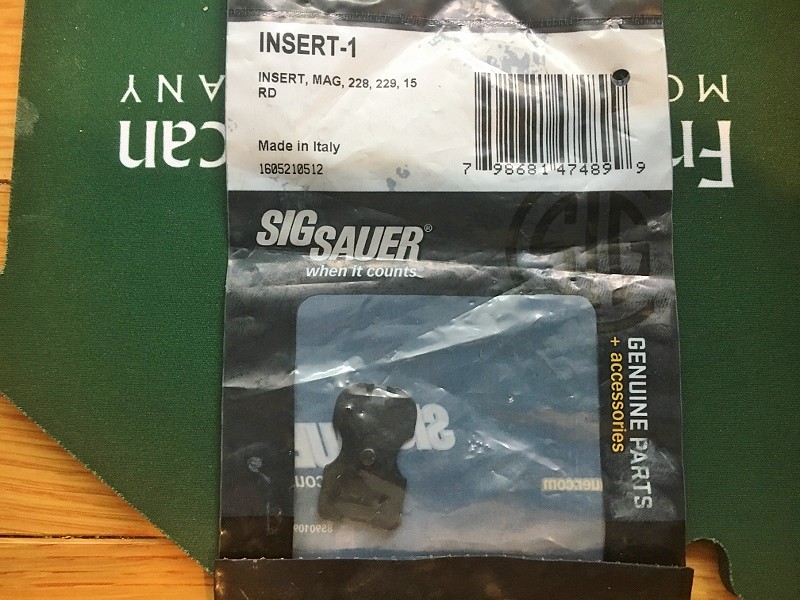

If anyone will use the mag insert/plate I have another one I don't plan on using and will mail it to them at no cost...first "I'll take it" and then follow up with address it's yours.  IMG_7956 (800x600) IMG_7956 (800x600) | |||

|

| Member |

Looks like the modified extension is too tight where it slips on and the rubber is too brittle and snaps...using the Pearce extension is pretty tight also but the rubber is pliable and no problems | |||

|

| Banned |

BTW thought I had a flash of brilliance. Had several old P229 10 rd mags. They have an extended butt plate that if put on the bottom of a P224 mag would have given pinky a grip but not real good fit as a small gap would exist where your pinky went. No joy. The 229 mag is slightly narrower at the base and the butt plate won't go onto the 224 mag. I was also hoping to use the floor plates with the PG-XD approach but they are also narrower and would not provide support for the 224 spring and would be too loose side to side if used with the 229 10 rd spring. So it's back to the PG-XD approach. | |||

|

| Banned |

Actually the material is very hard sort of like the old bakelite. No real give in it. | |||

|

| Banned |

I'll take it and thanks in advance 6 Jib Ct Hampton VA 23664 | |||

|

| Member |

It is your Ted...shoot me an email and I'll get it out to you. bjjennings1954@outlook.com | |||

|

| Banned |

I put my address in the post | |||

|

| Banned |

I was going to let the vendor on eBay know of the problem but the link to eBay for the item no longer works | |||

|

| Member |

Could you cut a slot in the XD grip extension like the sig base plate has allowing the spring to hold the XD extension in place? | |||

|

Member |

The area that would need to be cut through is a thicker portion of the base. I think a drill press would be easiest tool to use. One would need to drill several holes next to each other. I don't have a press and don't want to try it free hand. Sic Semper Tyrannis If you beat your swords into plowshares, you will become farmers for those who didn't! Political Correctness is fascism pretending to be Manners-George Carlin | |||

|

| Powered by Social Strata | Page 1 2 3 4 |

| Please Wait. Your request is being processed... |

|

© SIGforum 2025