Page 1 2

Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| Why don’t you fix your little problem and light this candle |

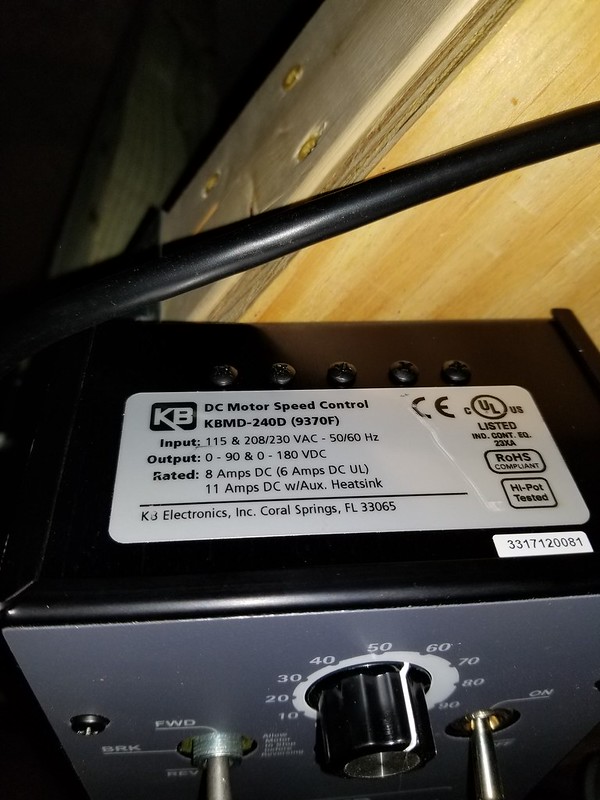

Sigforum, some advise please. I have a speed control that I use with my lathe (just an old student model Atlas) and honestly I rarely use it. I just purchased a used belt grinder and it has an electric motor (115v) that came with a on/off switch. The knifemaker that sold it too me said I could put my speed controller on it and nearly double the speed of the motor from 1700rpm to nearly 3k. For the life of me I cannot figure out if the motor can work with this speed controller. Here is the motor:  20200327_193330 by redstone71, on Flickr 20200327_193330 by redstone71, on FlickrAnd here is the speed control that I am thinking about using:  20200323_154920 by redstone71, on Flickr 20200323_154920 by redstone71, on Flickr 20200323_154901 by redstone71, on Flickr 20200323_154901 by redstone71, on FlickrCan I wire this KB speed control up to this much motor? Any advise would be awesome. FWIW, the grinder works just fine with the on/off switch, but I fixed the original speed control for the lathe so I am not using the new one anymore. This business will get out of control. It will get out of control and we'll be lucky to live through it. -Rear Admiral (Lower Half) Joshua Painter Played by Senator Fred Thompson | ||

|

Nullus Anxietas |

Nope. Your belt sander motor is AC. That speed controller outputs DC. Furthermore: The seller was mistaken. You can't increase the speed of an AC motor over the speed at which it's designed to run. You can decrease the speed of some AC motors by the use of pulse width modulation speed controls (merely varying the voltage is not sufficient), but you cannot increase it. "America is at that awkward stage. It's too late to work within the system,,,, but too early to shoot the bastards." -- Claire Wolfe "If we let things terrify us, life will not be worth living." -- Seneca the Younger, Roman Stoic philosopher | |||

|

| Why don’t you fix your little problem and light this candle |

And that is why I love this place. It just didnt seem right. For some reason I was focusing on the increase in amps (going from 1/3 HP motor to a 1.5hp motor) and didnt want to blow my speed control. I feel like a boob overlooking the AC and DC aspect. Thanks so much This business will get out of control. It will get out of control and we'll be lucky to live through it. -Rear Admiral (Lower Half) Joshua Painter Played by Senator Fred Thompson | |||

|

| Run Silent Run Deep  |

Sure you can...with a VFD. Variable frequency drive. _____________________________ Pledge allegiance or pack your bag! The problem with Socialism is that eventually you run out of other people's money. - Margaret Thatcher Spread my work ethic, not my wealth | |||

|

Nullus Anxietas |

Forgot about those. True, but, IIUC, you can't just slap any old AC VFD on any old AC motor. That's about as far as my greatly-limited knowledge of those goes "America is at that awkward stage. It's too late to work within the system,,,, but too early to shoot the bastards." -- Claire Wolfe "If we let things terrify us, life will not be worth living." -- Seneca the Younger, Roman Stoic philosopher | |||

|

| Shall Not Be Infringed |

^^^ A 460V Motor would require 'Inverter-Duty' Insulation to run on a VFD, however at 230V the Voltage Spikes in the PWM Output Waveform of the VFD (Pulse Width Modulation) would likely NOT exceed the Insulation Rating of the 230V Motor. And, you can DEFINITELY run a motor above the nameplate/base speed (above 60 Hz) with a VFD. ____________________________________________________________ If Some is Good, and More is Better.....then Too Much, is Just Enough !! Trump 47....Making America Great Again! "May Almighty God bless the United States of America" - parabellum 7/26/20 Live Free or Die! | |||

|

| Move Up or Move Over |

That motor is rated as class F. This indicates the manufacturer thinks it is inverter duty rated. Yes, you can sometimes slightly exceed the speed rating but not much and not for long. You might be able to increase the loads speed by changing the pulley. Before you do that I would run the motor under a decent load and check the amp draw. If you are near rated RLA the motor will fail if you push it too hard with trying to speed it up | |||

|

| Member |

You can't use that controller with that motor. AC motor/DC controller, 2 different types of electricity. You can up the cycles on an AC electric motor to speed them up a little, or decrease the cycles to slow them down a little, but nothing like you're asking. I've seen a lot of 50 cycle motors that run just fine on 60 cycle power (20% faster), I wouldn't go above that difference. But you're are not going to almost double the rpm of an electric motor. What you might be able to do is change your pulleys or gearing to get the belt to spin faster. This would be the easiest remedy, OR get a faster motor to begin with. A new 1.5 HP 3000 rpm AC motor is only $175-400 depending on the quality of the one you want. | |||

|

| Member |

If you are mechanically inclined and scrounge things like I do, you might find an old electric running/exerciser. The simple ones that are often draped with clothes in the bedroom? Conveyor belt that you run on for exercise? Yeah, one of those. They have DC motors and your controller would probably run it. Pull the motor and adapt it to your sander/grinder. Just check the motor and see that it doesn’t pull more amps than your controller provides. Your controller says, at a minimum, it will provide 8 amps. That is pretty good. It could be a really sweet set up. Read labels on both the controller and the motor. Further questions, get back to us. | |||

|

| I don't know man I just got here myself |

VFDs are generally used on 3 phase motors. I have never seen a single phase VFD to drive a single phase motor in the wild. | |||

|

| Member |

We use them a lot on yachts (VFD's and single phase motors). Marine air conditioning chillers (chilled water) on air conditioning compressors 230V single phase 60 hertz. Soft starts, they start the compressor slow and then ramp it up over a period of time that you set.....usually 60 seconds. We're limited in the amount of shorepower coming into the yacht and a 5 ton compressor starting normally when the entire 60'+ yacht is on a single 240V/50 amp cord is generally too much and trips the breaker on land. We also generally have VFD's on large blower motors which are somewhat similar to the OP's (for the engine room to adjust the fan speed), and some pumps run by the same type of motor.....also to speed up or slow them down. | |||

|

fugitive from reality |

In my building we have been converting all our fan and pump motors to VFD set ups. All our stuff is 460 three phase, but the principle is the same. The data plate shows class F insulation, whis is required for VFD operation. The big question is how old is the motor? Pre 1992 motors should not be converted to VFD, and it's also not recommended for 56 frame motors like the one you have. If you need more speed you could try changing shivs (pulleys) to get a faster drive ratio. http://www.industrialknowledge...r-vfd-compatibility/ _____________________________ 'I'm pretty fly for a white guy'. | |||

|

| Why don’t you fix your little problem and light this candle |

I bought a $50 craftsman band saw. strangely the guy was selling it because he couldnt 'turn it on' Evidently someone had taken the original motor out and had fixed it with a DC motor with a speed control, but sold him the saw, and motor but no control. he sold it to me cheap. oddly, when I was putting it together it had an AC motor with it as well. I will post pictures when I get it unloaded. I have no idea why you would need to run a band saw at variable speed. Anyway, I hope to set it up with the AC motor and use the DC motor and my spare controller with a blower for my coal forge. We shall see . . . Anyway, for now I will use the Belt Grinder with its on/off switch. Honestly, that 1700 RPM is pretty dang fast. So while I learn the ropes I will leave it alone for now This business will get out of control. It will get out of control and we'll be lucky to live through it. -Rear Admiral (Lower Half) Joshua Painter Played by Senator Fred Thompson | |||

|

fugitive from reality |

We have a battery powered low speed high torque band saw at work. The low speed allows you to cut whatever it is you're cutting without creating a shower of sparks or other debris, and it's easier to control than a sawzall. _____________________________ 'I'm pretty fly for a white guy'. | |||

|

Unflappable Enginerd |

Just to be clear, a single phase soft starter, and a VFD are NOT in the same realm. A soft starter allows you to reduce peak starting current by extending it out over time(the adjustable part). The power requirement is the same, over a longer period of time, but the peak is significantly lower. Hell, I have a single phase soft starter on my 230VAC AC compressor for my house, it's there for the same reason you mention, to reduce peak starting current. I installed it so I could use a smaller generator for my house. VFD's allow you a whole lot more flexibility, accel ramp type, ramp time, PWM frequency, vector speed control, decel ramp type, decel time... The list goes on... A modern VFD has HUNDREDS of parameters. __________________________________ NRA Benefactor I lost all my weapons in a boating, umm, accident. http://www.aufamily.com/forums/ | |||

|

| Member |

All of those are programmable on the soft starts that we have on some yachts. Accel ramp type, ramp time, frequency etc. While they don't have hundreds of user adjustable parameters, you can adjust the frequency with a knob and digital display. You adjust the frequency to change the chiller tonnage so it runs longer instead of short cycling on low demand on the chilled water loop on some yachts. Yachts have a lot of high tech systems. Reverse osmosis desalinization plants, gyro stabilizers, navigation systems, FLIR night vision, There are other ones, are like you say and just a sealed box with a predetermined ramp up time etc. Just a soft start. Some are set up simple and non user adjustable. I run some 3 phase yachts as well. Several yachts I run also have Atlas frequency converters which will take any power input, 120v/240v single phase/50 cycle/60 cycle/3 phase etc. and convert it to a certain output voltage. These aren't adjustable, but take any voltage and frequency and automatically convert it to say 240V single phase 60 hertz. | |||

|

Unflappable Enginerd |

Mkay... __________________________________ NRA Benefactor I lost all my weapons in a boating, umm, accident. http://www.aufamily.com/forums/ | |||

|

| Member |

Judging by your post in the VFD- well pump thread, I am not nearly as knowledgable as you in the VFD department. But, if I have a knob that changes frequency to speed up or slow down a single phase AC motor as much or as little as I want, it would be connected to a Variable frequency drive? Hatteras Yachts installs these on their 2 very large 240v AC engine room blower motors, as you can draw as much as 50 amps with them if you turn them up all of the way. I've hooked my Fluke to one and the frequency does change at the motor. On the Atlas frequency converters we have (I know different than a VFD) you can adjust/set output voltage and frequency on them. But once you set it for the equipment the yacht has, you never change it. | |||

|

| Shall Not Be Infringed |

This thread is starting to get off into the weeds, and 'some' bad info is being provided. The info at the link above is primarily targeted at 3-phase applications and somewhat lacking in important detail. It is also a bit misleading, though it does include the following disclaimer, "Please note that these are generalizations." With respect to the bolded statements above re: Class F Insulation....Nope, Insulation Class, such as 'Class F', is a Temperature Rise rating, NOT a Voltage Spike Withstand Rating. While most 'Inverter-Duty' Motors have 'Class F' Insulation (or better, e.g. Class H), NOT all 'Class F' insulated Motors are Inverter-Duty Rated. Question(s) for the OP: What is the max. speed you want/need to operate the Belt Grinder? How much Current does the Belt Grinder draw now at the fixed/base speed (RLA @ 1725 RPM)? ____________________________________________________________ If Some is Good, and More is Better.....then Too Much, is Just Enough !! Trump 47....Making America Great Again! "May Almighty God bless the United States of America" - parabellum 7/26/20 Live Free or Die! | |||

|

Unflappable Enginerd |

Generally speaking, it's more efficient to run VFD's on 3 phase motors, because as I noted, single phase motors would need to be de-rated on a VFD (generally). You're probably looking at a combination of motors and uses, sound's like 3 phase 230VAC? Yes? 3 phase 230VAC VFD's are common as dirt. I work on industrial equipment, which is almost exclusively 480VAC 3 phase, some on VFD's but most on contactors/relay starters. Mind you, we're talking industrial systems with hundreds of motors/starters/VFD's. Sorry for the thread derailment... __________________________________ NRA Benefactor I lost all my weapons in a boating, umm, accident. http://www.aufamily.com/forums/ | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

© SIGforum 2025