SIGforum

Drilling steel plate - Cobalt or Titanium Bit?

July 28, 2021, 01:19 PM

P250UA5Drilling steel plate - Cobalt or Titanium Bit?

So, I have an adapter plate for my engine stand to be able to mount the rotary engine properly.

It was made from scrap steel & will work great for it's purpose. Problem was with my dimensions.

The bolt holes I provided are a bit too far off center & the end of the plate hits the dipstick tube on the engine.

This leaves me with 2 options:

Drill new holes, closer to center & clear the dipstick.

Or

Get thick washers/spacers, sufficient enough to clear the tube using the existing holes.

If I go the 'drill new holes' route, which bit would be best suited to drilling a (4) 1/2" dia hole in 1/4" (might be 1/8" will have to check when I get home tonight) steel plate?

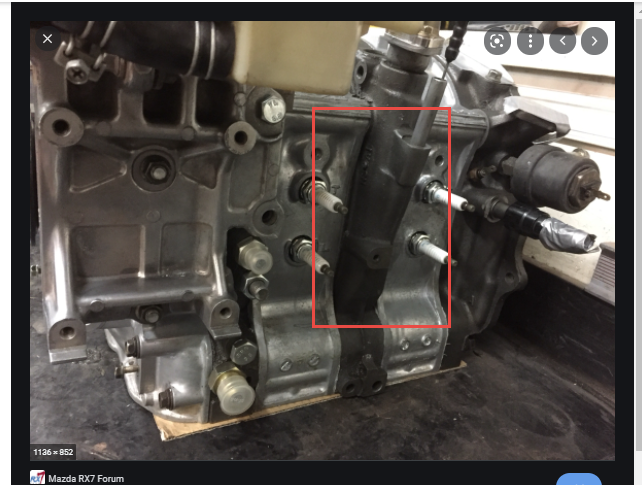

Engine stand adapter:

This is with the stand side up. Would need to drill 4 new holes between the center & ones marked on the yellow line.

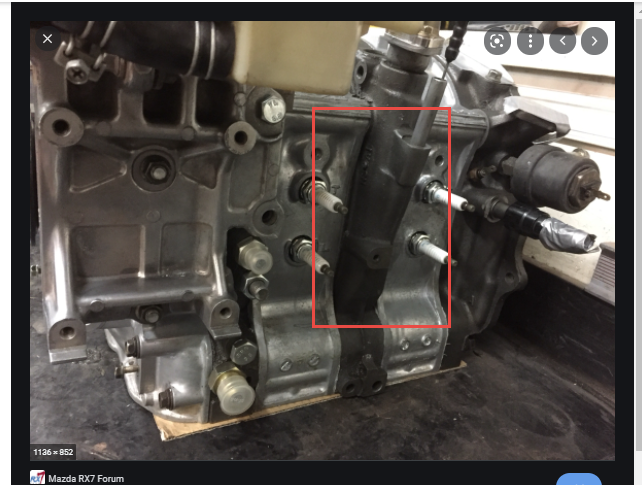

Stock image of a Mazda 13B, showing the dipstick tube & point of contact:

The Enemy's gate is down. July 28, 2021, 01:41 PM

trapper189Black oxide HSS bits for mild steel will be your best value. Use oil while you are drilling. I’d drill 1/4” first then switch to the 1/2”.

July 28, 2021, 01:51 PM

c1steveCobalt is mostly for stainless, etc. It is extremely sharp and hard, but brittle. I would not use cobalt unless in a drill press, mill, etc.

-c1steve

July 28, 2021, 02:45 PM

hrcjonThis is mild steel. A quality(!!!) HSS bit will do fine. If you want it Tin coated have at it, but tool life won't be an issue for 4 holes so its really a money waste.

“So in war, the way is to avoid what is strong, and strike at what is weak.”

July 28, 2021, 02:56 PM

sigmonkeyPull some M2 AP belt ammo and use an M1.

"the meaning of life, is to give life meaning" ✡ Ani Yehudi אני יהודי Le'olam lo shuv לעולם לא שוב! July 28, 2021, 03:06 PM

P250UA5Thanks gents.

Monkey, these need to be fairly precise, so the M1, while a fun option, probably won't work. I'm not that good of a shot.

The Enemy's gate is down. July 28, 2021, 04:01 PM

beermannA little oil while you are drilling helps, most people drill too quick and burn up bits... go slower than you think. Also apy a lot of pressure and keep the drill very steady, your bit (nitride coated is fine) will thank you.

July 29, 2021, 04:24 AM

TRIOHSS is fine for mild steel. Consider getting a split point drill bit for your first smaller hole size. It would take less pressure to cut. To get a good start, center punch your layout locations. Use a center drill first, then the two drills to size. Less chances of your drill walking if you do it this way.

--Tom

The right of self preservation, in turn, was understood as the right to defend oneself against attacks by lawless individuals, or, if absolutely necessary, to resist and throw off a tyrannical government.

July 29, 2021, 06:37 AM

henryazProperly clamped/mounted in a drill press or mill/drill, HSS bits will work fine. I would start at about 400rpm, and go slower if the steel is hard. Feed slowly. Keep the hole well lubricated with cutting oil. The waste piece coming off the drill should be a spiral piece, rather than chips, and don't let it start burning. Adjust feed and speed as necessary.

Doing it this way, I've drilled a 5/8" hole through 1/4" x 2" x 2" steel tubing (two holes actually as it was all the way through). Using a HSS bit, and no smaller hole to start. This was for the 5/8" pin in a receiver hitch mount.

When in doubt, mumble July 29, 2021, 08:37 AM

220-9erDrill a small (1/8 or so)pilot hole first then work your way up.

Another problem is the rust because it's hard and very abrasive and will wear the bit out much quicker than the steel. Try hitting the areas to be drilled with a sanding disc first to remove the surface rust.

___________________________

Avoid buying ChiCom/CCP products whenever possible.

July 29, 2021, 08:55 AM

phydoughI’ll be the dissenting vote here. A little grinding of a slot for the dipstick tube and spacers/washers should work fine. It’s not like you are trying to hang a full dressed Dodge 440 off your adapter.

July 29, 2021, 10:17 AM

P250UA5Thanks again for the further recommendations.

Even though the dipstick is a vestigial component (dry sump), I want to avoid modifying the 'block'.

Thinking more on it, I do have the 'legs' for the engine stand, which should suffice for thick washers/spacers.

Just need to source the 4 bolts to the engine, in a longer length.

The Enemy's gate is down.