Page 1 2

Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| Member |

P320C, new out of the box, unable to move the take down lever, stuck. After putting on heavy gloves I was finally able to force it down. Then had to use a rod to punch it out. Looks like the o-ring is too tight on the grip module. Removed the 0-ring and all seems ok. Other than jamming up the TDL what purpose does the o-ring serve? | ||

|

| That's just the Flomax talking |

Some lubricant might help. | |||

|

| Member |

Make sure the magazine is removed before trying to fully rotate/remove the take down lever...ask me how I know. Glad no body was watching me as I almost resorted to your method. Not certain what the O-ring was intended to do but I figured the SIG engineers had a reason. I left it in. After I figured out what I was doing wrong (see above), the take down levers come out easily on my three P320 pistols. Put some lube on the O-ring and it goes in/out easily. Exploring another galaxy. | |||

|

| Member |

I did drop the mag. Not sure oil is the correct solution for rubber? I will try a little silicone grease. Not impressed with quality control, never had any firearm with the action stuck coming out of the box.

| |||

|

| Member |

OK got the o-ring back in with a little silicone grease. A littler better, but still not right. Ordered a new TDL, O-ring, and grip module. Needed the large grip anyway. Let you know what corrects the problem. No way that I have the only stuck o-ring, has be others.

| |||

|

| Do---or do not. There is no try. |

Several people---including me---have had this issue. There was apparently one run of takedown levers that ran very slightly large. I called and got a replacement, and it's perfect. Call Sig CS, whover you talk to should know what you're talking about. | |||

|

| Member |

Thanks, will do. | |||

|

| Member |

Called SIG CS, Chris, he was not aware of any issues with the TDL. He advised that my gun had just left the factory March 1 and would have been checked at that time. I could return the gun for service or order a new TDL and o-ring. He could waive the shipping but not the parts cost. So I ordered the TDL for $16 and the o-ring for $4.00. My TDL looks like it is 20 years old with all the bluing rubbed off from using a glove in attempts to loosen it up. If this does not work it goes back to SIG for repairs. Still not a shot fired. Chris advised that maybe I should jiggle the guide rod and spring while pressing down on the lever. He was actually serious, not April's Fool. I must have missed the jiggle part in the manual, although it did advise to rotate the "flats" until vertical. Not sure what should be vertical the "flats" or the user. In any case, my tension rod/spring is round, so it must apply to the user. I have been carrying a gun since 1971, all purchased new or issued new (Smith, Sig, Beretta, Glock). My favorite was the P226 made in W. Germany, least favorite, let you know in a few weeks. The P320 looks good, feels good and is a great modular concept but it has to be reliable and accurate for me to carry. Other owners, same problem: More vocal SIG may be having a quality control problem with the TDL and or o-ring, despite what CS told me. https://www.youtube.com/watch?v=mcmlVR4fR6A https://www.youtube.com/watch?v=jNtwoCIVVSY https://www.youtube.com/watch?v=gTKDpIrSnf8     This message has been edited. Last edited by: GeoTracker, This message has been edited. Last edited by: GeoTracker, | |||

|

| Member |

FWIW, I recently replaced my original (Jan 2015) P320C 9mm TDL with the new flat style TDL and a new O-ring. The original rotated with only slightly more effort than my classic P-series. The new flat style takes three hands. I am clueless as to what Sig did, since the only issue was the external/exposed shape of the TDL itself. Regarding the O-ring, my presumption is that it keeps the TDL from wandering. Never read anything definitive though. I used some silicone on the O-ring yesterday and it is SLIGHTLY easier to rotate. A suggestion: Use one of those rubber pads designed for removing jar tops. Gives a little more purchase and saves your thumb. ______________________ An expert is one who knows more and more about less and less until he knows absolutely everything about nothing. --Nicholas Murray Butler | |||

|

| Member |

I scuffed off the finish on the take down lever shaft with a 3M pad. Just enough to remove the finish not the metal. That helped along with lube. Exploring another galaxy. | |||

|

| Member |

^^^^^ So obvious that I never thought of it. Maybe I'll take a little Flitz paste to the shaft. As you mentioned, just want to slick it up...not change dimensions. Thanks. ______________________ An expert is one who knows more and more about less and less until he knows absolutely everything about nothing. --Nicholas Murray Butler | |||

|

| Member |

Looks like the slot on the TDL is not aligned correctly with the Takedown Safety Lever that goes in the grove as the lever turns. The slot/grove may be just a little bit off center or the Takedown Safety Lever is not lined up correctly. I should have a new TDL from SIG tomorrow and I will put them side by side. I have the newer flat lever. The slot is located on the TDL closest to the o-ring.This message has been edited. Last edited by: GeoTracker, | |||

|

| Member |

I know of at least 3 different part numbers for the SIG P320 Take Down Lever: My new P320 was made in FEB 2017 and came with part #777Y101 (which was stuck on arrival), the slim line version is being shipped to replace the larger original style TDL and has part #1300777-R. The replacement TDL being shipped to me this week is part #1300777-03-R. I don't know if the part number makes a difference but it usually a way to track modifications or batch control. I was told the #1300077-03-R was in stock but it did not ship with the O-RING-1 that was also on my order. The Grip Modules are almost the same way but with no difference in the part number and owners are calling them Ver 1 for the original grip module and Ver 2 for the new ones that fit the new flat TDL and come with a part to replace the Slide Catch Lever Release Assembly Kit KIT-320-SCL. | |||

|

| Member |

SIG P320 Stuck Takedown Lever problem seems to be solved. Installed a new TDL and O-ring. It is still a little stiff but no gloves required. I think it will loosen up ok. SIG Part Number: O-RING-1 and 1300777-03-R   | |||

|

| Member |

Thanks for the update and pics. Now we have THREE versions. Never a dull moment. The flat TDL I bought in January is the same as your original - part #1300777-R. Have the same problem. Apparently it has been replaced with version THREE - part #1300777-03-R. Hence the "03" reference in the part#. This is mildly aggravating, since Sig obviously had a problem with the prior non-03 version. Now I have to spring for another TDL to rectify the problem. Aargh. My presumption is that they revised the PITA second TDL version rather than the O-ring to correct the issue. Are there any obvious differences between the two TDL versions that you can discern? ______________________ An expert is one who knows more and more about less and less until he knows absolutely everything about nothing. --Nicholas Murray Butler | |||

|

| Member |

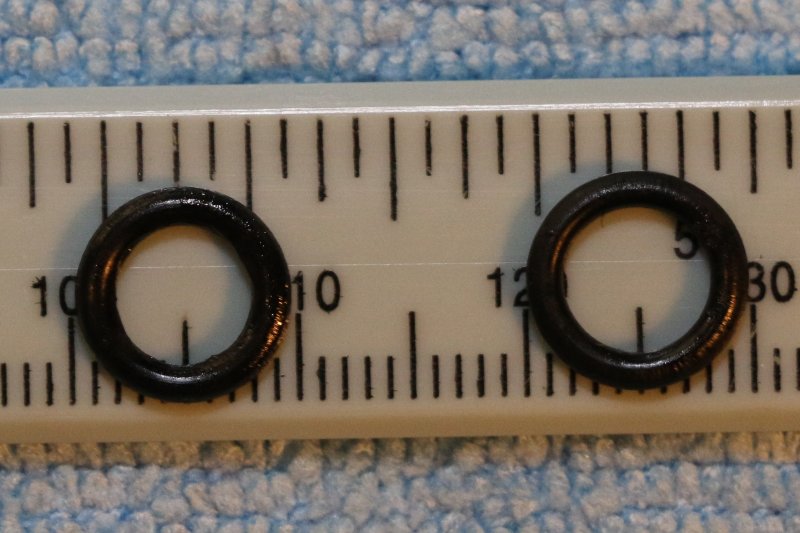

The two differences that I see are in the o-rings, the size of the grove in the TDL that snaps in the right side of the grip module when you put in the Takedown Lever, and how much o-ring is showing above the o-ring grove. The new o-ring is on the left and appears to be slightly fatter. The new TDL is on the bottom part of the photo. Notice the wider grove to the left that snaps into the grip module and how the the o-ring stays lower in the grove next to the lever. This may indicate that the new TDL has a deeper o-ring grove. The differences are very slight, but seem to indicate that the new TDL has more play in the grip ring snap and less friction on the o-ring.   | |||

|

| Do---or do not. There is no try. |

Your photo shows the takedown lever that I received which fixed my problem.   | |||

|

| Lucky to be Irish |

Same issue I have on my 320c. My full size TDL rotates easily. The 320c is VERY difficult to rotate. I spoke with Sig CS and their solution was to "move the guide rod around". Sorry, no joy. Maybe with time and use... | |||

|

Member |

I have the same issue on the 320RX compact I recently acquired. I didn't have this issue with the 320 compact which was replaced. After swapping out my threaded barrel a few times and cleaning both barrels a few times, the TDL is still difficult but at least I'm not ripping the skin off my thumb anymore. I hope with some more use and it will become even easier to rotate. Sic Semper Tyrannis If you beat your swords into plowshares, you will become farmers for those who didn't! Political Correctness is fascism pretending to be Manners-George Carlin | |||

|

| Member |

Yes, there is hope. The flat TDL I referenced in my post above is SLOWLY loosening up. I have a P320C, an X-change kit and a SC grip frame module. Consequently, I swap the FCU out/in more than most. It's at the point where I can turn it without protecting my thumb with a rag. Very stiff, but now able to turn it without loud screams. ______________________ An expert is one who knows more and more about less and less until he knows absolutely everything about nothing. --Nicholas Murray Butler | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

© SIGforum 2025