Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| Frequent Denizen of the Twilight Zone  |

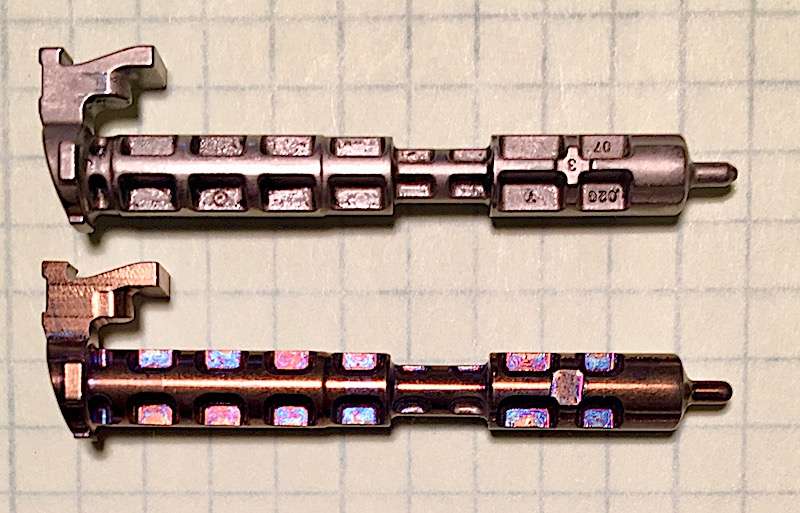

It's interesting that the LSI P365 striker appears to be very similar in design to the original P365 OEM striker. Some people are preemptively installing these strikers, some are replacing broken strikers with the LSI one. I don't know how many people are doing this, only scattered anecdotal reports.  As opposed to the new P365 striker.  So the question that comes to my mind is whether or to what extent the design of the original striker had any thing to do with the striker breakages or if it was a material issue, MEM vs non-MEM or if it was a combination of the two? In the latter case, the MEM part would need a redesign in order to be sufficiently durable because it was a MEM part. However, no one knows how the LSI will perform in the P365 as there are probably not that many installations or evidence. No one really knows why SIG redesigned the striker, that is, was it because of the breakages, or some other reason. Or, finally, were the breakage just a matter of some faulty strikers and had nothing to do with the material or design? SIG just redesigned if for a different reason. Perhaps the redesign had to do with light primer strikes or primer drag, although SIG has denied this is an issue they would need to fix. It's all speculation without SIG indicating why there was a redesign. Perhaps the redesign was about "improving" rather than "fixing".This message has been edited. Last edited by: SIGWolf, | ||

|

| Left-Handed, NOT Left-Winged! |

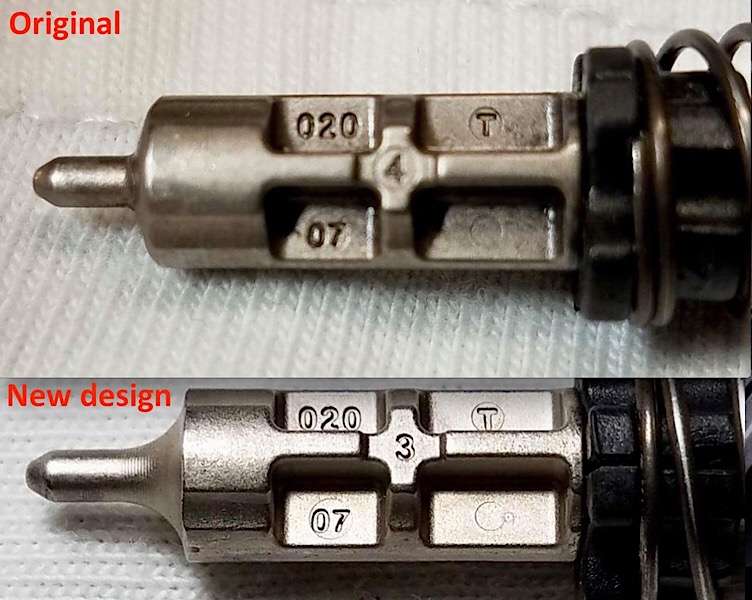

The new design has a more gradual radius between the larger body and the striker pin, it is also relieved back. Breakage was likely caused by the primer drag since it creates a lateral shear force on the pin. The radius change reduces the chance of breakage at the transition point because sharp changes create increases in local stresses and places for cracks to initiate. The second change I believe prevents the striker from "bottoming out" in the striker bore in the slide when it is fired. Tolerance variation between the slide and striker could result in light primer strikes if it bottoms out on the shoulder instead where intended (I think it has been stated there is another positive stop on the striker.) The design and tolerances and materials may be perfectly sound as designed. However, manufacturing variances in material quality, quality of the the MIM process, out of tolerance conditions, etc. may result in failures in some cases - a few percent as we have seen. So it would be in Sig's best interest to improve the design and implement changes, but fix-as-fail for the older ones. While people may not like this, it is generally how things are done. For cars, safety issues result in recalls, while non-safety issues that affect reliability are generally fixed as needed under extended warranties or TSB's. Cars do not have "mandatory recalls" in most cases - they notify you and you take your car in, they don't force you to. An exception to that may be emissions related issues like VW diesels being intentionally non-compliant with emissions regs. And design updates to fix issues, reduce warranty cost, improve customer perceptions, and reduce cost, etc. happen all the time even during a "model year" or generation as needed. Big changes that the customer will see (and that can be used for marketing purposes) usually happen at the Model Year / Generation changes. Small stuff happens all the time, often lumped into intervals, like 90 days or 180 days between batches of changes. And those are generally not announced to the public or made "upgradable". If it fails, you get the upgrade. If not, there is no need for it. | |||

|

| Frequent Denizen of the Twilight Zone  |

Thanks Lefty! | |||

|

| Member |

While I cannot say for sure, on mine, it appeared that the striker was bottoming out at this point.  <><><><><><><><><><><><><> "I drank what?" - Socrates | |||

|

| Frequent Denizen of the Twilight Zone  |

I haven't seen any modifications at that point in the pictures that have been posted, but they have all focused on the tip of the firing pin. | |||

|

Go Vols! |

On the topic of 365 strikers - Any idea why the 365 manual has a spot it says do not oil or it will cause striker malfunctions? How sensitive is this issue? | |||

|

Prepared for the Worst, Providing the Best |

I can't speak to the P365 specifically, but the P320 manual says the same thing, and I did experience an issue. I tried to keep lube and solvent out of there, but over many sessions and thousands of rounds (I clean every time I shoot) I started experiencing light strikes, so I broke it down and discovered a lot of gunk and crud in there gumming up the works. There was definitely lube and solvent in there, too...it's pretty much impossible to properly clean the gun without some making it's way in there. I cleaned the striker assembly thoroughly, dried it off and re-assembled, and had no more issues. IMO, it probably would have gunked up eventually anyway even without any oil in there (I was shooting some really filthy lead handloads), but I'm sure it didn't help. I now remove the striker and clean it more regularly. | |||

|

| Member |

Aside from the tendency for dirt/dust/fouling to collect in oil and gunk up the channel, as mentioned above, having oil in the striker channel can cause misfires if the oil gets ahead of the striker tip. You can get hydraulic compression that will rob the striker of a lot of energy, but that usually takes quite a bit of oil in there. The same can happen with firing pins in hammer-fired guns. I once was shooting a match with a guy who was having problems with his new SR-9. When he field stripped it, I noticed that the striker channel in that gun is exposed on the bottom, and he had oiled it all the way down the length of the channel. He didn't know how to disassemble the slide, so we wiped out as much as possible, reassembled and dry fired it a few times, then wiped it again. He got through the rest of the match, but I advised him to figure out how to get it apart and clean it out thoroughly after he got home. If you are worried about stuff getting in there, you can always remove the striker and squirt a little polymer-safe gunscrubber in through the hole in the breech face. <><><><><><><><><><><><><> "I drank what?" - Socrates | |||

|

Junior Member |

Is the LSI striker fully compatible with the new slides? LSI told me they do not plan on updating their design to match the new Sig striker. | |||

|

| Member |

Then they don't plan on selling too many of these things | |||

|

| Frequent Denizen of the Twilight Zone  |

As I understand it, there is no "new slide". The new striker is interchangable with no changes in the slide at all. I expect there are many who will change the striker because it is a MIM part regardless of design, or because they think it will resolve the primer drag. That they are not going to change the design would seem to indicate they believe at least, that they are resolving a MIM issue and not a design issue with the original striker. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

© SIGforum 2024