Page 1 2

Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| Certified Plane Pusher |

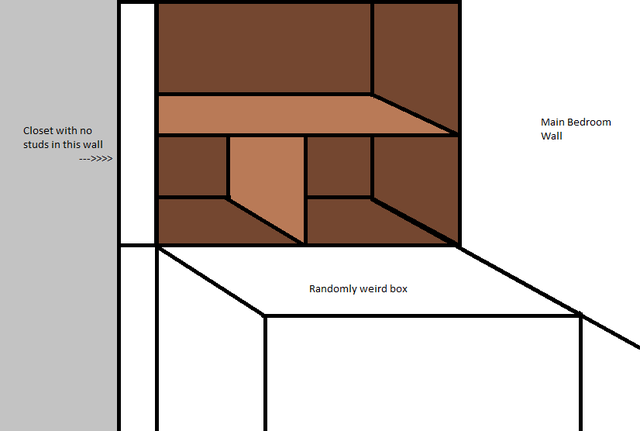

I have commissioned to build a built in cabinet for my mother in law. It's a basic square box but one side doesn't have any studs to mount to because the side is up against her closet. I'm looking for ideas on how to build it. What are the best materials to build the built ins with? I have a week to get it done with almost an unlimited budget. Situation awareness is defined as a continuous extraction of environmental information, integration of this information with previous knowledge to form a coherent mental picture in directing further perception and anticipating future events. Simply put, situational awareness mean knowing what is going on around you. | ||

|

| Three Generations of Service  |

My first thought would be cabinet-grade veneered plywood and matching hardwood face frames. For example, oak veneer plywood with solid oak frames. Be careful when following the masses. Sometimes the M is silent. | |||

|

| Certified Plane Pusher |

Somethin like this:  Situation awareness is defined as a continuous extraction of environmental information, integration of this information with previous knowledge to form a coherent mental picture in directing further perception and anticipating future events. Simply put, situational awareness mean knowing what is going on around you. | |||

|

| Member |

Disclaimer: Real, professional woodworkers will suggest much better technique. My suggestions are about a combination of strength and expediency. Go get one of these: Kreg Jig Then get some cabinet grade 3/4" plywood of your choice, and go to town. If you want to dress the front up, use said recently acquired Kreg Jig to make the face frames PHPaul suggested, using some clear lumber. | |||

|

Member |

^^^ I use a Kreg jig. I doubt there's a pro, except for very exclusive artisans, that's doing dove tails. Time is money to the pros. Demand not that events should happen as you wish; but wish them to happen as they do happen, and you will go on well. -Epictetus | |||

|

Quit staring at my wife's Butt |

It really depends on what type of tools you have available, I could build that in a number of ways. buttjoint , confirmat, dado, miter, dovetail, dowel pin. need more info 31 years in the cabinet business. | |||

|

Nosce te ipsum |

Last month I hacked together a vanity for a heavy-use college bar bathroom. ½" mahogany plywood with 1" x 2" corner strips. Glued and screwed everything. If I only was able to cut the plywood square it might have achieved a "C" rating. When it comes to carpentry I'm like the tavern handyman who installed a toilet while I was away. Just enough knowledge to be dangerous. It is harder than it looks to make something simple, and I bet a decent table saw with a big deck would have made my job much easier, in getting square cuts. | |||

|

| Three Generations of Service  |

Absolutely. As a kid, maybe 10 years old, I was briefly involved with a 4H woodworking program. The instructor's view was that you had to master hand tools first. Rip saws, cross-cut saws, back saws in a miter box, cutting shapes with a coping saw, jointing with a block plane, etc. ad nauseum. I sucked at it. Really, REALLY sucked. Put me right off woodworking for a long time. Power tools, properly set up and used, almost invariably improve your results. Knowledge of how and when to use various joints is obviously important, but once the decision is made, power tools greatly simplify things and improve accuracy and fit. I'm no cabinetmaker, but since I started using a table saw, compound miter saw, jointer, planer, router and biscuit joiner, I've put out some pretty decent stuff. If I had to do it with hand tools, it would look like crap. I just don't have the patience or the eye for it. Be careful when following the masses. Sometimes the M is silent. | |||

|

Certified All Positions |

If you're doing "paint grade," Then you need no more than some birch ply, and some poplar for the front edges. What are the overall dimensions of this? If paint grade, all the joints can be butt and screwed through, with the face glued and finish nailed. Depending on the size, I'll let the shelves into the sides 1/4 inch and use glue with the screws. For the back you don't need more than 1/2 ply, but 3/4 won't hurt. I let the backs into the sides at least 1/4 always, it looks neater and helps assembly. Are you trying to do stain grade? Arc. ______________________________ "Like a bitter weed, I'm a bad seed"- Johnny Cash "I'm a loner, Dottie. A rebel." - Pee Wee Herman Rode hard, put away wet. RIP JHM "You're a junkyard dog." - Lupe Flores. RIP | |||

|

| Certified Plane Pusher |

Arc, the box it self will be 40 5/8 wide by 28 5/8 deep and 55 3/4 tall. I'm looking for paint grade. Her house is a little bit older and painted would match the room. And somehow I'm going to have to put some doors on it. Situation awareness is defined as a continuous extraction of environmental information, integration of this information with previous knowledge to form a coherent mental picture in directing further perception and anticipating future events. Simply put, situational awareness mean knowing what is going on around you. | |||

|

| member |

So, you'll be basically ripping two sheets of plywood down to 28 5/8". This will give you one side and one bottom/top from each rip. Then one more sheet will provide you the inside pieces for shelving. Overall, 3 sheets of plywood, plus whatever you decide make the back out of (3/8 to 1/2" should be sufficient). You will have a couple of nice 3/4"x17"x8-0" rippings left over for future use. | |||

|

Quit staring at my wife's Butt |

| |||

|

| Certified Plane Pusher |

That does help. The only problem with going 24 deep is that the right side is up against a wall and so is the left. The ledge that it will be sitting on is a lot deeper than 29inches. It is probably 34ish. I measured to have it be flush with the closet side wall. I have no problem buying extra materials in order to have it the way I need it. So you are suggesting that you dado the box together and for the shelves? I have a portable table saw that is dying for some dado blades. Situation awareness is defined as a continuous extraction of environmental information, integration of this information with previous knowledge to form a coherent mental picture in directing further perception and anticipating future events. Simply put, situational awareness mean knowing what is going on around you. | |||

|

Only the strong survive |

Here is a shelf I built using 3/4 and 1/2 inch Birch plywood. The back, top, bottom and sides are 3/4 inch while the vertical spacers and shelves are 1/2 inch and all the joints are dadoed and glued while the 3/4 inch was drilled for use with wood screws IIRC.  In your case for a deeper bottom, just make the bottom deeper to be used as a writing or desk surface.This message has been edited. Last edited by: 41, 41 | |||

|

| Certified Plane Pusher |

41 that looks great, just about exactly what I'm looking to do. Dado and glue it is! Situation awareness is defined as a continuous extraction of environmental information, integration of this information with previous knowledge to form a coherent mental picture in directing further perception and anticipating future events. Simply put, situational awareness mean knowing what is going on around you. | |||

|

| Member |

You can dado with a saw if the fences will adjust wide enough, or you can dado with a router, using strips for constraining guides. | |||

|

| member |

A router makes a cleaner cut, but you can avoid tear out on a table saw by using dado sets with a dedicated table insert, made of wood. Make the blank, then carefully (slowly) wind the dado blades up into to the wood insert, to just the depth of cut you need. I usually move the fence over to hold the insert down during this operation. Fence on one edge, and a piece of wood clamped to the table to hold the other edge of the insert. | |||

|

Only the strong survive |

I ripped the 3/4 and 1/2 plywood on the same setup so the width would be exact for all the pieces. Next you cut the pieces to the correct length. I set the dado to cut one ply deep on the 1/2 and 3/4 inch plywood. The dado will give a uniform cut versus a saw blade which would also be time consuming. I even dadoed the side ends for fitting to the top and bottom. The 3/4 inch was fasten with wood screws and glue while the 1/2 shelves only used glue.  41 | |||

|

Member |

Is this to be mounted on a wall? For the cabinets I've built that hang on the wall I rip a 1x4 board in half at a 45 degree angle, mount one to the wall (level) and the matching side flush to the back of the cabinet at or near the top.  I'd put a face frame around it, then mounting doors should be pretty straight forward. Edited for spelling and added a picture | |||

|

| Certified Plane Pusher |

No this box won't be hanging from a wall. It will more or less be a built in. It's an odd setup. I appreciate that you guys put up with my MS Paint Skills to try to convey what I'm talking about.  Situation awareness is defined as a continuous extraction of environmental information, integration of this information with previous knowledge to form a coherent mental picture in directing further perception and anticipating future events. Simply put, situational awareness mean knowing what is going on around you. | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

© SIGforum 2024